Unveil the potential of Nicomatic’s crimpflex system, a groundbreaking advancement in industrial connectivity. This article delves into how Crimpflex effectively resolves issues in cable and circuit assembly, providing unmatched flexibility and reliability across various applications.

In the realm of industrial connectivity, professionals often face challenges related to the performance and longevity of wiring and circuit configurations. Customary methods, such as soldered connections or rigid cabling systems, while widely used, frequently enough fall short in terms of adaptability and durability, especially in demanding environments like aerospace and healthcare.

Understanding Nicomatic’s Crimpflex Breakthrough

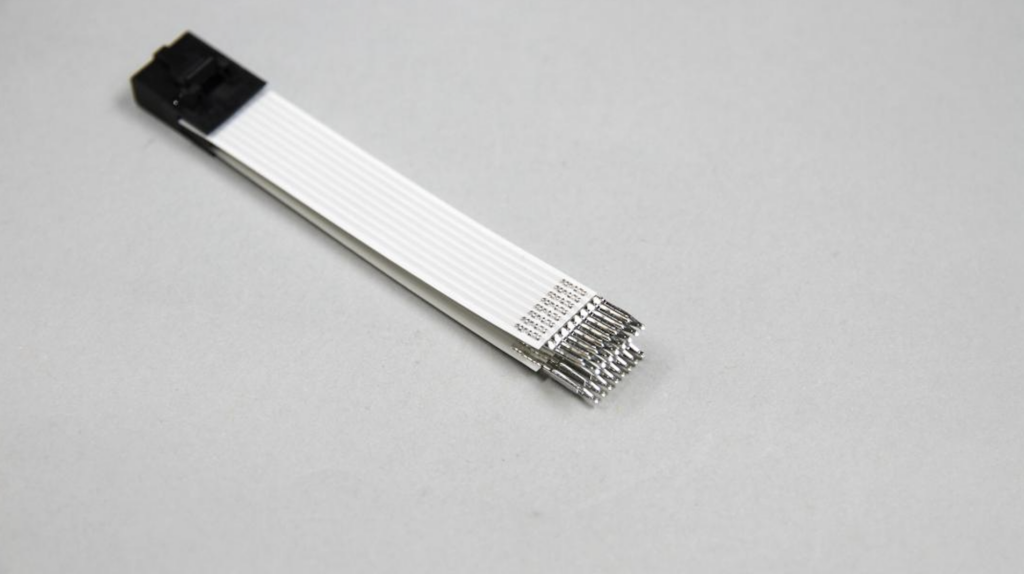

This is where nicomatic’s Crimpflex system shines. Designed to overcome these challenges, Crimpflex utilizes an innovative crimping technique that effectively engages with a variety of materials, including flexible printed circuit boards and ribbon cables. This unique method guarantees a six-point connection: two points for structural support and four points to ensure optimal electrical conductivity.

Key Features of Crimpflex

Think of Crimpflex as a highly adaptable connection solution that conforms seamlessly to the shapes and constraints of the devices it supports. Imagine a flexible printed circuit board fitting perfectly within compact medical devices, or a flat wire maintaining strong connectivity in military equipment designed to meet specific requirements. Crimpflex meets these needs with remarkable precision and reliability,offering crimp thicknesses ranging from 75 to 350 micrometers and the ability to handle up to 3 amperes per contact point. available pitches of 2.54mm and 1.27mm facilitate integration into a wide array of system designs. Contact configurations include straight or right-angle orientations, male/female options, and single/double-row setups, providing extensive versatility for various project demands.

Installation Tools and User-Friendliness

For installation, Nicomatic has created specialized crimping tools for Crimpflex, ranging from handheld devices that accommodate up to 5 contact points to robust manual and electric presses designed for applications requiring 10 simultaneous connections. This variety of tools ensures that users can implement and maintain systems with maximum ease and efficiency.

Why Opt for Crimpflex?

Crimpflex offers a sophisticated connectivity solution that surpasses traditional wiring methods with a lighter, more adaptable, and reliable option. Manufactured in France, this system promises exceptional quality and performance while delivering unmatched flexibility for tailored applications, from standard industrial production to custom solutions for specialized needs like medical devices or membrane keypads.

Explore the complete article here, or visit the Nicomatic website for more data.