Innovative UAV Rotary Engines

Explore advanced solutions from 4</strong top global manufacturers

View Suppliers showcase Your Solutions

SUPPLIER SPOTLIGHT

Contemporary unmanned aerial vehicles (UAVs) that exceed the typical size of small unmanned aerial systems (sUAS) require substantial power for both their flight mechanisms and complex payloads. As the dimensions of thes aircraft increase, the limitations of battery technology become increasingly evident, leading to restricted flight durations and payload capacities.

UAVHE, a pioneer in hybrid propulsion systems, has introduced an innovative rotary engine-generator solution designed to address these challenges for medium-sized UAVs.

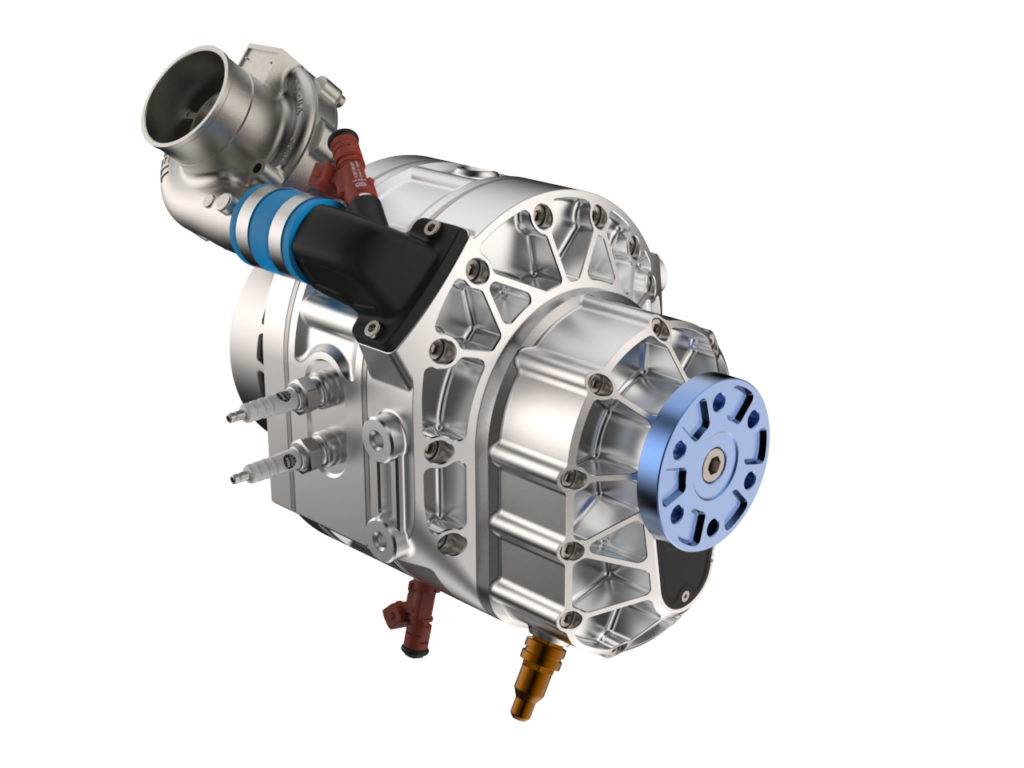

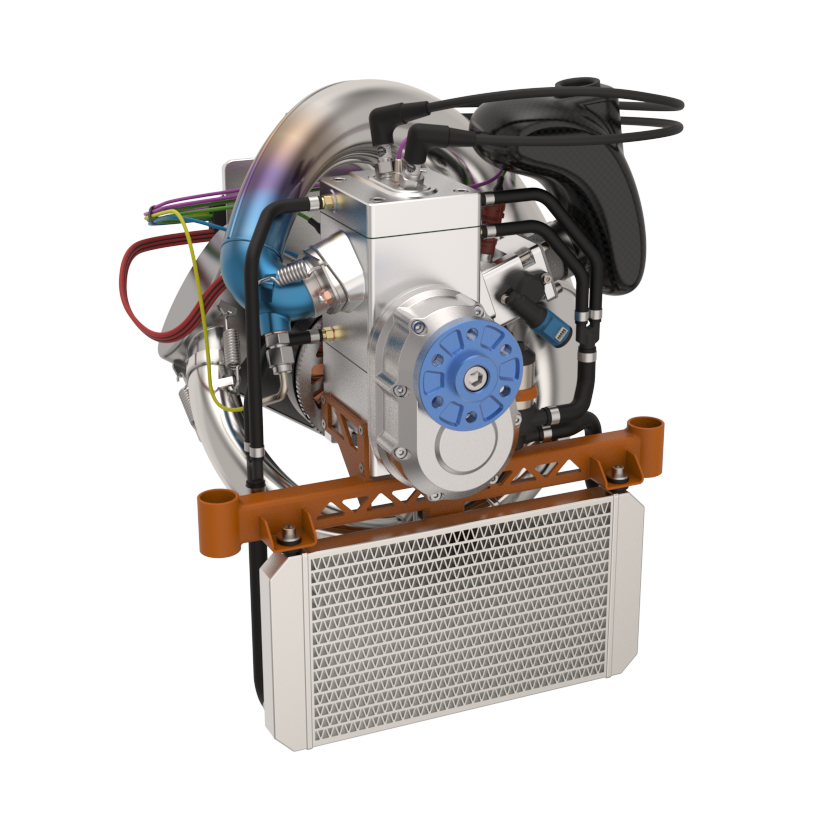

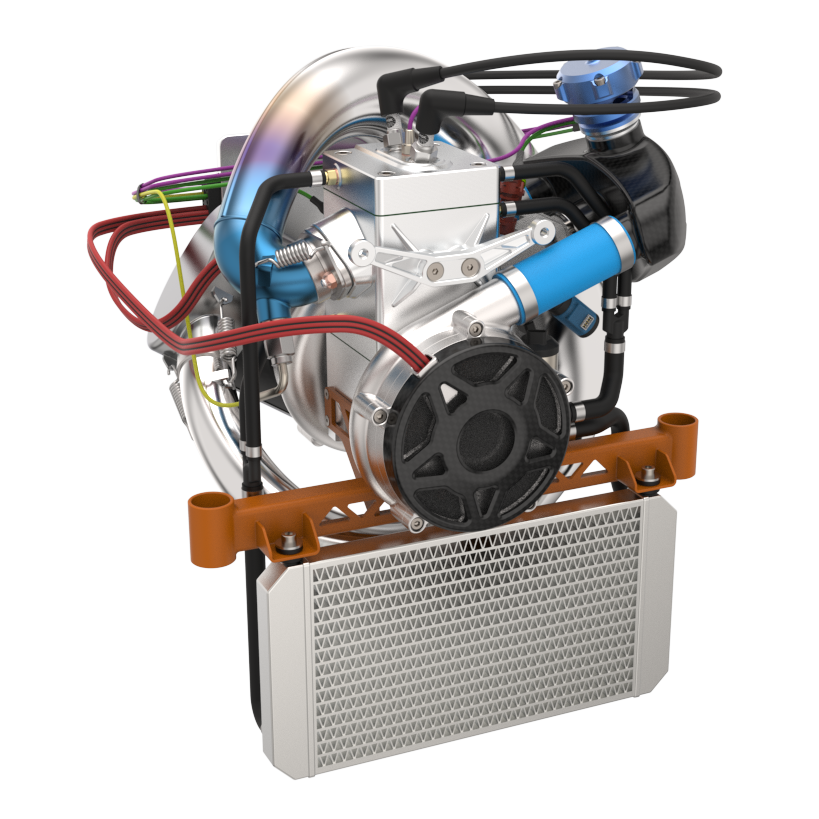

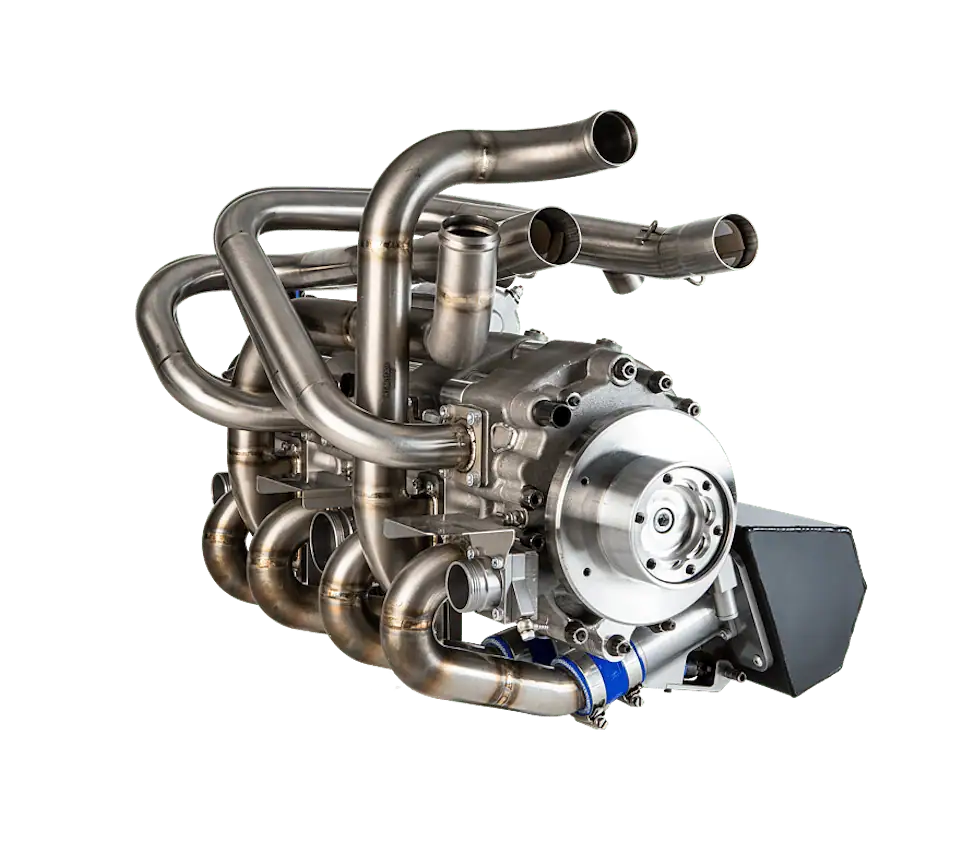

The RW79 engine produces 11 kW of power, sufficient to lift a multirotor weighing between 50-60 kg or a fixed-wing UAV of up to 100 kg. This output can be further augmented with additional booster batteries. Utilizing a Wankel-type air-cooled fuel injection engine equipped with an electronic supercharger, this system capitalizes on the fact that the energy density of fuels like kerosene is significantly higher—by a factor of tens—than even the most advanced lithium batteries. additionally,it harnesses the benefits of hybrid powertrains to optimize fuel efficiency and minimize consumption.

Historically, Wankel engine designs have faced skepticism within the aviation sector due to early reliability issues stemming from inferior components and technologies.However, UAVHE has meticulously engineered the RW79 using cutting-edge materials and manufacturing processes to meet the demanding requirements of UAV applications while extending maintenance intervals. The conventional nickasil coating on the engine’s stator has been replaced with a thin insert sleeve crafted from whitewashed cast iron, and the apex seals are made from a specialized tungsten carbide alloy. Furthermore, the rotor’s apex grooves are coated with diamond-like carbon (DLC), and the rotor temperature is regulated by periodically applying a fresh fuel mixture.

Advanced Technology for Maximum efficiency and Durability

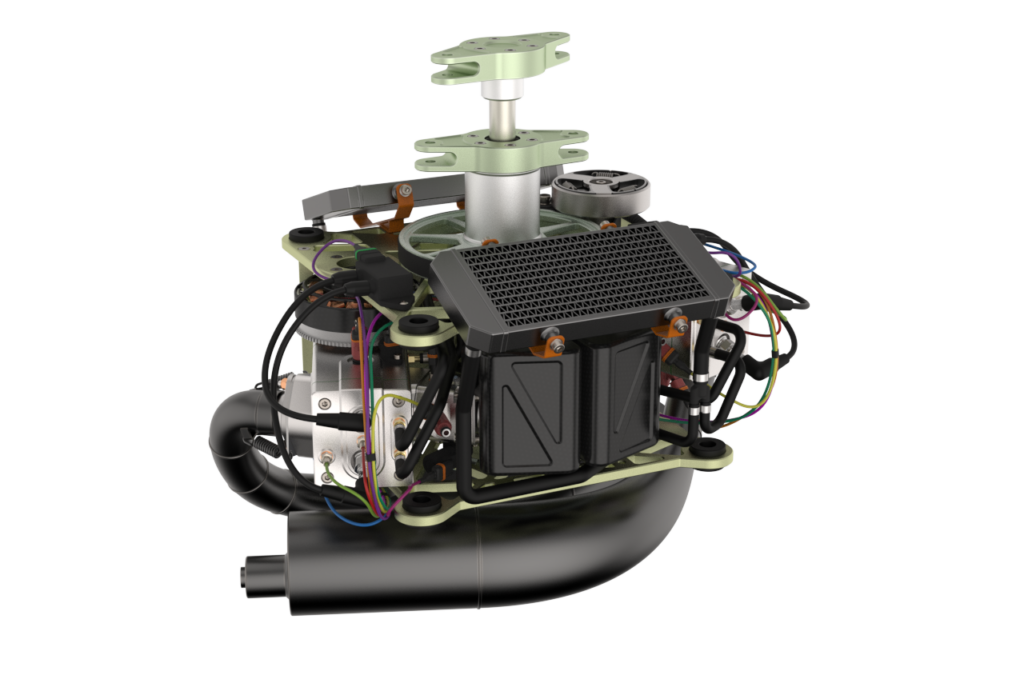

UAVHE has integrated state-of-the-art processing technology and intelligent control algorithms to ensure the RW79 operates at peak efficiency,maximizing fuel utilization.The system recalibrates its fuel map for each operational cycle, ensuring optimal combustion of the fuel-air mixture.

To minimize wear and vibration, precise load management is employed. A bank of supercapacitors is charged by the generator during the active phase of the operation cycle, where the engine directly rotates the shaft, maximizing engine load. Conversely,during the majority of the cycle,when the shaft is driven by inertia,the load is reduced. This approach results in a smoother torque curve,enhancing reliability and longevity.

Military-Grade Design and Comprehensive Testing

The RW79’s design meets the stringent requirements of both commercial and military UAVs, featuring military-spec connectors, galvanic coatings, robust filtering, and software compliant with DO-178 standards.All components are sourced from rigorously vetted European suppliers and undergo extensive testing and documentation to ensure complete traceability throughout the production process.Each engine assembly is subjected to testing on a dynamometer within a thermobaric chamber before shipment.

The RW79 is derived from UAVHE’s larger RW300 model, a well-established platform that has been in production for several years, accumulating thousands of accomplished flight hours. With its low fuel consumption, lightweight design, and straightforward integration, the RW79 serves as an optimal power solution for a diverse range of medium-sized UAV applications.

For further information about the RW79 hybrid propulsion system for UAVs, please visit UAVHE’s website or contact them directly.