Innovative Hybrid Propulsion Systems

Explore advanced solutions from 8</strong top-tier global providers

View Suppliers Showcase Your Solutions

SUPPLIER SPOTLIGHT

As the use of drones expands, the demand for extended flight durations and increased payload capacities is growing. In many cases, the value of the cargo being transported can exceed the aircraft’s cost, leading designers to prioritize enhanced reliability. This is especially vital for larger UAVs, where the risk of secondary damage during emergency landings is meaningful and frequently enough uninsured.

Two Distinct Design Philosophies

In the UAV engine sector, two main design philosophies have taken shape:

First Philosophy: Often referred to as “RC-aircraft modeling,” this approach emphasizes creating a cost-effective yet functional product with a limited operational lifespan.

Second Philosophy: Known informally as “General Aviation,” this method anticipates future certification requirements, aiming to meet or exceed FAR33 standards.Products developed under this philosophy typically incorporate system redundancies, high-quality materials, and thorough pre-design calculations and simulations. Techniques used in large aircraft and military-grade products are extensively applied. Consequently, thes products are considerably more expensive than those from the “RC-model” category, with lifespans extending into hundreds or even thousands of hours.

UAVHE SL’s Commitment to Quality

Engineers at UAVHE SL embrace the “general Aviation” philosophy in their engine design and manufacturing processes. The company features a cutting-edge in-house production facility, outfitted with advanced CNC machines, casting equipment, a heat treatment and electroplating workshop, and a extensive testing and metrology lab. Most components, including electronic control units, are manufactured in-house, adhering to aerospace and military specifications.

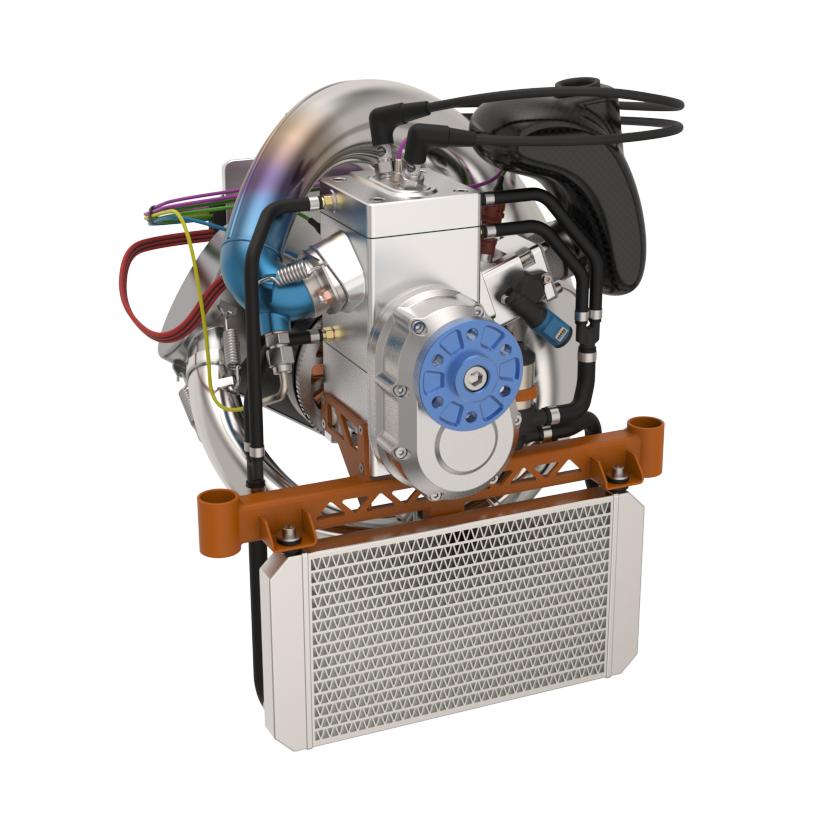

One of their latest innovations, the RW300H engine, is tailored for large UAV helicopters. The ‘H’ signifies both Hybrid and Helicopter. This engine boasts a 65hp Rotary (Wankel type) liquid-cooled design, featuring electronic heavy fuel injection, an electronically controlled supercharger, an integrated transmission with a final ratio of 15:1, and dual alternator/boosters.

Technical Features of the RW300H Engine

A 22kW electric motor is directly connected to the crankshaft, serving as both a starter and a “smart flywheel.” To mitigate torque fluctuations, power from the generator is directed to the ballast battery from supercapacitors only during the active stroke (when fuel ignites) and is withdrawn during the compression phase. By adjusting the offset and phase overlap of the motor and booster torque, the overall torque profile is smoothed, significantly minimizing vibrations.

The appeal of hybrid systems like the RW300H lies in their ability to electronically and precisely manage torque.Adjustments occur at speeds and accelerations comparable to electric motors, but the power source is fuel tanks rather than limited-capacity batteries. This leads to a notable increase in flight time, reduced refueling intervals, and all the advantages associated with internal combustion engine (ICE) aircraft.

The transmission system includes a centrifugal idle clutch and a two-stage gearbox.The engine operates in several key modes: idling at 3500rpm, midrange at 6000rpm, and flight mode at 8800rpm. During idle and midrange, the centrifugal idle clutch disengages, preventing the engine from rotating the transmission while still generating electrical current through the alternator.

Equipped with numerous sensors, the engine and transmission utilize advanced algorithms to monitor the power plant’s condition during operation, aiding in failure prevention and maintenance scheduling.

The FADEC control system, connected via a CAN bus, enables the engine ECU to manage all pumps, fuel supply systems, and coolant circulation through the radiators. The cooling system for the battery pack and ESC controllers is integrated into one of three independent cooling circuits.The heat removal process is regulated by the duty cycle and heat exchange rate through the radiators, ensuring reliable operation even in extreme temperatures, ranging from -40°C to +55°C. Developers can access engineering test kits, which include an engine on a subframe, complete with all necessary radiators, pumps, controllers, wiring, source codes for integration, and monitoring software, facilitating easier dyno and integration testing.

For more facts about the RW300 engine and its underlying technology, click here >>