Innovative UAV Wankel and Rotary Engines

Explore advanced offerings from 4 top global manufacturers

View Suppliers Showcase Your Solutions

SUPPLIER SPOTLIGHT

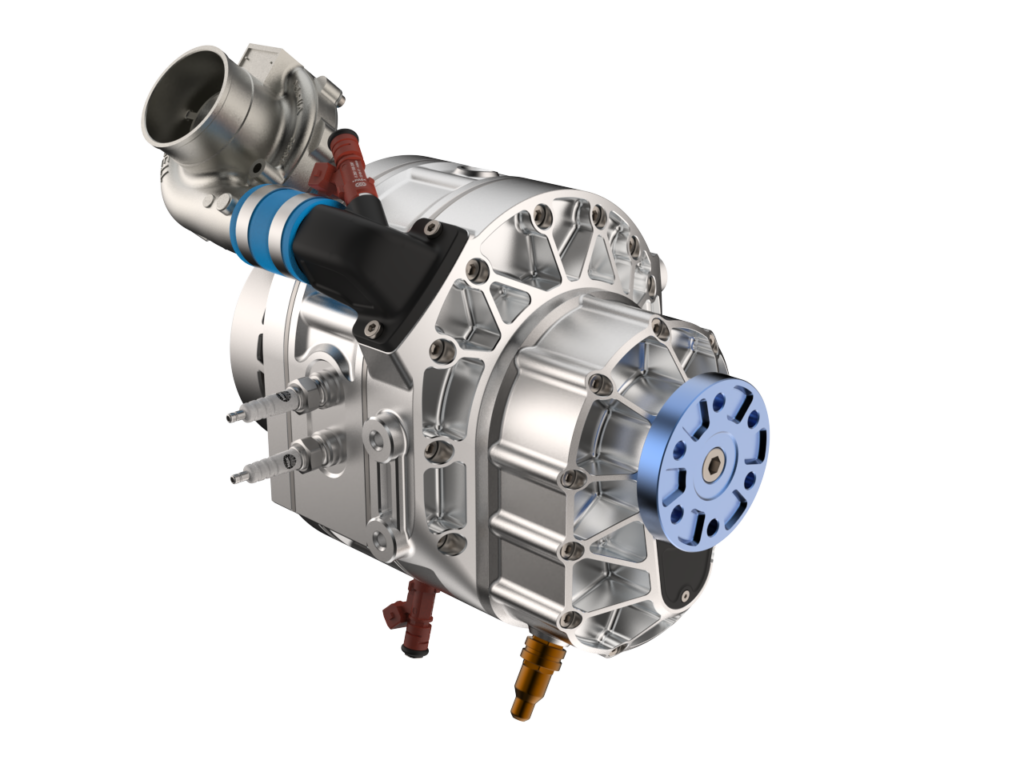

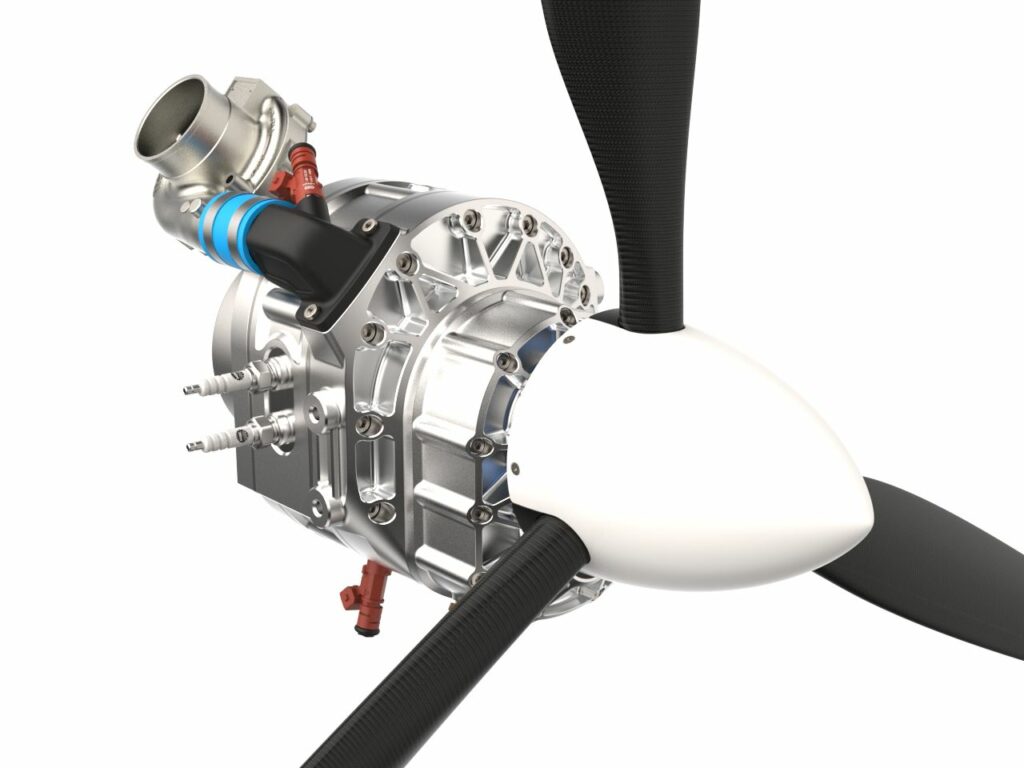

UAVHE, a manufacturer specializing in internal combustion and hybrid engines based in Barcelona, has launched the RW1-300C, an innovative hybrid Wankel engine tailored for unmanned aerial vehicles (UAVs). This engine is meticulously crafted using advanced aeronautical technologies and methodologies, featuring a Wankel rotary design with an integrated transmission and a variable pitch propeller hub. The starting price is set at €11,900.

The RW1-300C excels in maintaining consistent speeds, making it ideal for fixed-wing UAVs with ample electrical demands and vertical take-off and landing (VTOL) aircraft. It incorporates a two-stage electronic fuel injection system,where part of the fuel mixture is injected directly into the combustion chamber and intake manifold. To adapt to varying altitudes, the engine is equipped with an electric supercharger that can be adjusted smoothly based on operational conditions. For enhanced reliability, both the fuel pump and pressure regulators are duplicated. The engine is designed to operate efficiently with a wide range of fuel types, including aviation gasoline, automotive fuel, and heavy fuels like aviation kerosene and jet fuel.

This hybrid engine features an 11kW generator and a reversible electric starter/booster, allowing for a temporary power boost during takeoff or dynamic maneuvers. The robust starter ensures reliable ignition of heavy fuels even in extreme cold and low-pressure conditions. At cruising speed, the engine can provide up to 10 kW of electric power, and 2 kW when idling with the propeller stationary.

The cooling system is a liquid, double-circuit design featuring two autonomous loops, radiators, and pumps. If one circuit fails, the engine can still operate, albeit at reduced power. The variable capacity cooling pumps ensure optimal temperatures during operation and facilitate smooth cooling after missions.

The transmission system includes a centrifugal idle clutch, which prevents the propeller from rotating until the engine reaches 3000 rpm, and an integrated gearbox with a 1:3.2 ratio. The gearbox housing also functions as an oil cooler. Additionally,a brush block is integrated into the body to manage the variable pitch propeller.Oil temperature sensors and metal chip detectors are included in the gearbox, with data relayed to the control unit via a CAN bus.

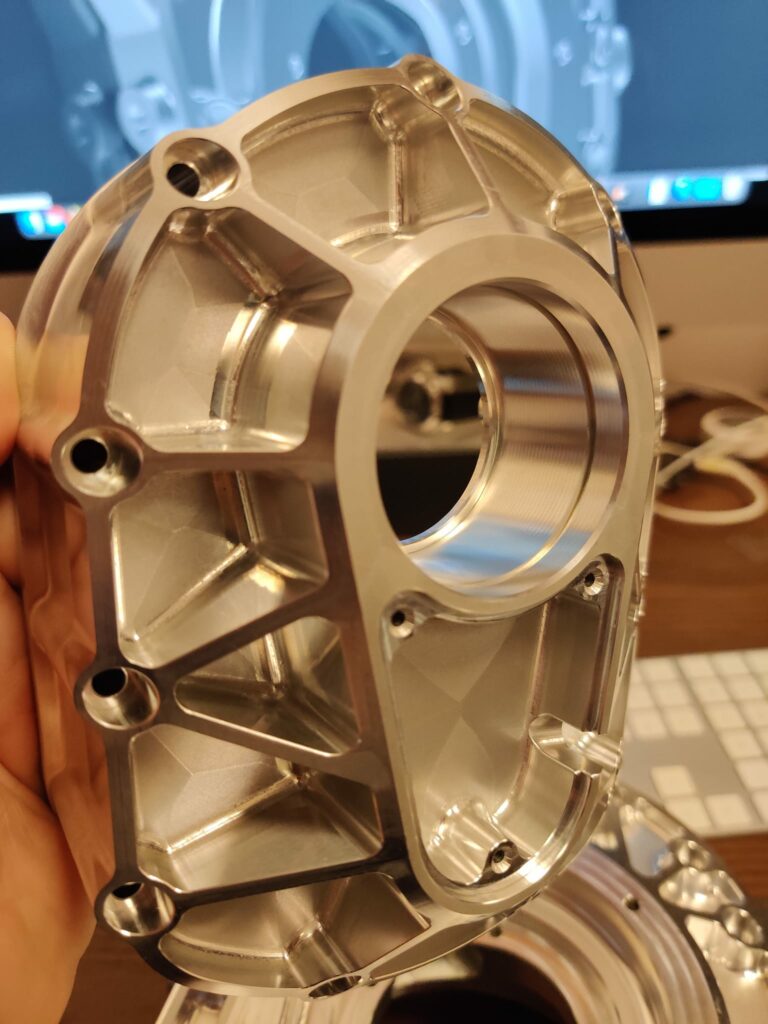

Materials and Construction

- The engine casing is crafted from duralumin alloy.

- The rotor is hollow, cooled by the fuel mixture, and constructed from aluminum forging.

- Apex channels are treated with electroplating.

- Seal apexes are made of tungsten carbide, while sidewall slots are polished and coated to prevent seizing.

- The crankshaft and internal gears are forged from steel.

- Bearings operate on polished and hardened surfaces.

- The engine’s exterior is hard anodized for durability.

- All fasteners are made from stainless steel or titanium.

- Connectors are sealed to military specifications.

- The combustion chamber (stator) consists of a thin cast-iron sleeve with cast-iron side walls connected to labyrinth cooling channels.

Andrei Bogdanov from UAVHE commented on the RW1-300C, stating, “This model stands out as one of the pioneering Wankel hybrids designed with aeronautical principles in mind. The redundancy in the fuel pump,pressure regulators,and cooling systems enhances reliability. The ability to adjust speed or torque, along with an electric booster that increases power by 20% during takeoff, empowers UAV manufacturers to elevate their designs to a new standard. This engine represents a significant advancement in systems integration, tailored specifically for aircraft developers.”

Learn more about UAVHE’s RW1-300C Hybrid Wankel Engine hear >>