HP Additive Manufacturing Solutions stands at the forefront of 3D printing innovations,driving remarkable advancements and customization in the drone sector.

Reliable Additive Manufacturing Solutions for Drones: Engineered for Excellence, Scalability & Innovation.

Our industrial-grade additive manufacturing systems facilitate swift production of components, from functional prototypes to final products, ensuring consistent dimensional precision and isotropic material characteristics.

HP’s technology leads the industry in producing the lightest components in additive manufacturing, yielding structural parts, fuselages, and entire wings that surpass competitors in weight efficiency. This advantage arises from the advanced design versatility and scalability inherent in the process. The HP Digital Manufacturing Network (DMN) connects a worldwide network of partners, promoting distributed production and efficient supply chains for intricate aerospace components. Users can upload their CAD files and receive parts printed to the high standards expected from HP Additive Manufacturing Solutions.

discover HP Additive Manufacturing Solutions:

- HP Multi Jet Fusion Technology

- HP Jet Fusion 5600 Series

- Case Studies & Applications

HP Multi Jet Fusion Technology

Our HP Multi Jet fusion (MJF) technology transforms the landscape of drone manufacturing, offering unmatched rapid prototyping and customization capabilities. By employing a distinctive multi-agent and multi-pass approach, it meticulously controls the properties of each voxel in every print, allowing for intricate details and optimal mechanical properties, thus enabling the creation of complex geometries that customary CNC machining cannot achieve.

Watch the video below to learn more about the HP MJF process:

Highlighted Product: HP Jet Fusion 5600 Series

advanced 3D Printers for Drones & Robotics

The HP Jet Fusion 5600 series supports high-volume production of durable 3D printed components, enabling efficient scaling of your drone manufacturing operations. It accommodates a variety of materials, including flame-retardant options and those with smooth finishes, featuring a build volume of 380 x 284 x 380 mm and a production speed of up to 3466 cm³ per hour.

The capabilities of this robust printer can be further enhanced with our HP 3D Process Development package. This workflow allows for the customization and fine-tuning of essential process parameters tailored to specific submission needs, enabling analysis and iteration untill your drone components are perfectly optimized. The finalized settings can then be transmitted to the HP Jet Fusion 5600, ensuring maximum repeatability at scale.

HP Additive Manufacturing solutions: Success Stories & Applications

Seed-dispersing Drones

Data courtesy of Inverto Earth

Inverto Earth AG leverages HP MJF technology to manufacture 3D components for drones designed to disperse seeds, aiding in the restoration of coastal ecosystems like mangrove forests. The design flexibility provided by MJF allows for the release mechanism to be tailored for over 60 seed varieties, ensuring durability in challenging and muddy conditions.

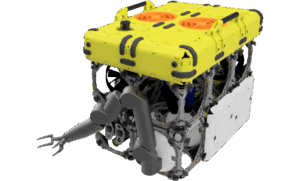

Modular Underwater Vehicles

Data courtesy of Frameworks Robotics

Framework Robotics, a developer of unmanned underwater vehicles (UUVs), utilizes HP MJF technology to create modular systems for diverse marine applications, including oil and gas, defense, and renewable energy sectors. this technology helps the company address delamination, waterproofing, and durability challenges associated with FDM-printed parts, while also providing quicker turnaround times for clients.

Last-mile Delivery Drones

Data courtesy of Blueflite

Blueflite employs HP Multi Jet Fusion technology to fabricate components for its lightweight delivery drones. Utilizing HP Nylon 12 material, they achieve a 25% reduction in fuselage weight while maintaining structural integrity. The high-resolution capabilities of MJF support intricate designs such as ribs and lattices, enhancing durability and design versatility for components like body panels, motor mounts, and landing gear.

AI-Driven Autonomous Drones

Data courtesy of VECROS

VECROS utilizes HP Multi Jet Fusion to produce components for ATHERA, an autonomous UAV equipped with AI for obstacle avoidance and real-time data collection. HP MJF provides the necessary smooth surface finish, durability, and design flexibility for integrating various payloads, facilitating rapid prototyping and design refinement to meet the company’s sophisticated operational demands.