Uncover the cutting-edge techniques utilized in the production of carbon fiber propellers as mejzlik Propellers elaborates on their innovative manufacturing methods. from detailed design to the finishing touches, delve into how the company employs prepreg and hot press technology to craft propellers of outstanding quality at their facility in Europe.

Accelerated Curing Technique

Mejzlik employs a rapid 7-minute curing process that operates at 140°C under high-pressure conditions,followed by a controlled cooling phase for further processing. Each cycle’s temperature data is meticulously recorded and archived, ensuring full traceability. Materials are precisely cut using automated CNC plotters, specifically tailored for this rapid curing method.

European Craftsmanship

Located in the Czech Republic, Mejzlik prioritizes sourcing components locally. This approach not only fosters environmental sustainability but also considerably supports local community advancement and economic growth.

Production benefits

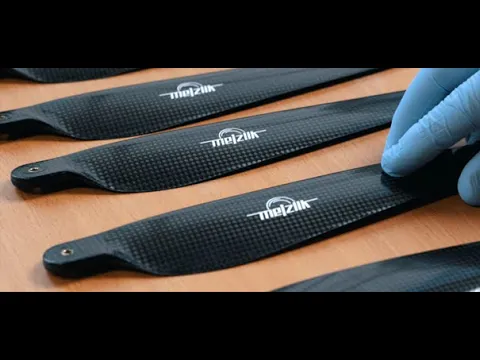

The manufacturing system at Mejzlik features highly repeatable processes and scalable design capabilities. The company adeptly meets high-volume production demands without sacrificing precision or quality. Mejzlik’s specialized applications extend to multicopter designs and VTOL propeller expertise, addressing both commercial UAV requirements and military specifications.

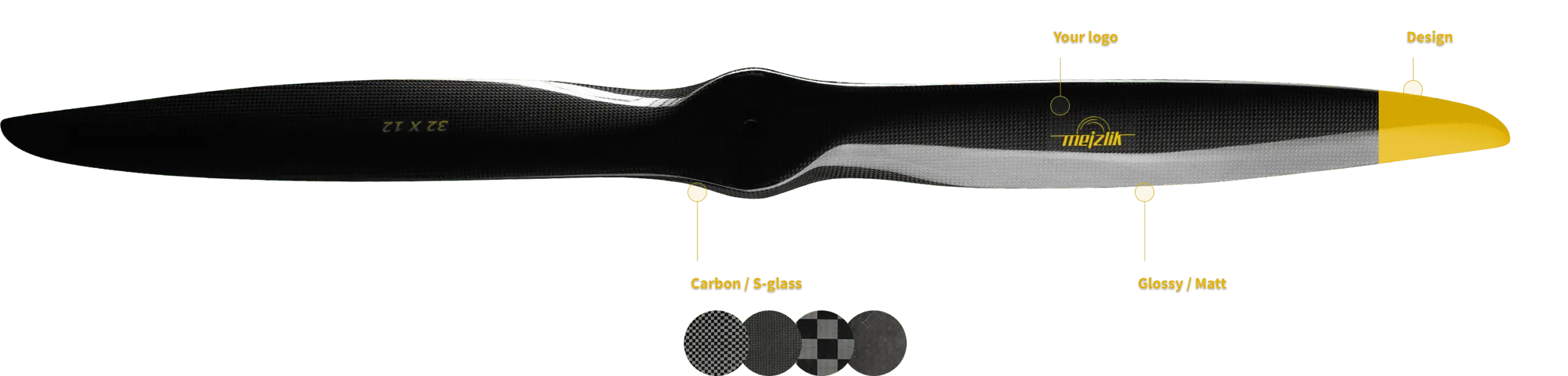

Compliance and Material Standards

Mejzlik adheres to stringent aviation regulations, with lamination technology that is FAA-certifiable. The company utilizes state-of-the-art carbon fiber to produce lightweight, high-strength components that significantly enhance performance characteristics.

Quality Control and Longevity

The manufacturing process at Mejzlik is characterized by transparency, with aviation-grade traceability integrated at every stage. Their products demonstrate exceptional impact resistance, capable of enduring harsh environments while ensuring long-lasting reliability. the automated precision of their systems minimizes the potential for errors, resulting in consistently high-quality outputs.

In-House Expertise and Custom Solutions

Mejzlik designs, manufactures, and tests all equipment internally, providing complete control over the entire production process. They offer “Build to Print” services, allowing clients to utilize their advanced facilities for existing designs. This service is especially beneficial for those with finalized concepts seeking premium manufacturing capabilities.

Current Production Capabilities and Future Prospects

Currently, Mejzlik produces propellers with diameters reaching up to 42 inches, including individual blades of the same size. Future expansion plans aim to diversify their range of prepreg-made propellers. These components exhibit enhanced fatigue resistance, promising improved durability and extended lifespans.

For the complete article, click here, or visit the

Mejzlik Propellers website for more information.