Ophir optronics Solutions has published insights on how their continuous zoom lenses meet the UAV industry’s low-SWaP demands while ensuring superior optical quality.

OVERVIEW: the UAV sector has witnessed remarkable advancements and expansion in recent years. This growth has led to the emergence of drones equipped wiht elegant infrared imaging systems, featuring compact detectors with smaller pixel sizes, which pose challenges for UAV optics.

To optimize imaging performance in line with detector advancements, lens quality must be enhanced, enabling high-resolution visuals. Three essential criteria, known as SWaP—Size, Weight, and Power consumption—must be prioritized to ensure that optical assemblies are appropriate for UAVs and drones. Essentially, optics should be compact, lightweight, and energy-efficient to maximize flight duration.

Optical manufacturers face the challenge of creating lenses that deliver sharp, clear images across the entire zoom spectrum, achieving an MTF close to the diffraction limit while adhering to stringent SWaP specifications. Additionally, these optics must endure the demanding environmental conditions typical of various UAV applications, notably in defense scenarios.

INDUSTRY CONTEXT: The UAV market is rapidly expanding, with analysts from the Teal Group projecting global UAV production to reach $135 billion over the next decade¹. drones equipped with high-performance EO/IR camera payloads are increasingly utilized across diverse imaging applications.

The drone sector encompasses defense, governmental, and commercial uses.In defense and government, drones are employed for military surveillance, law enforcement, border security, and search and rescue missions. Between 2009 and early 2017,over 347 law enforcement and emergency response agencies in the U.S. acquired drones².

Fig.1: UAV featuring a compact gimbal payload

In the commercial drone sector, demand is on the rise. Drones equipped with thermal imaging technology are increasingly vital for inspecting electrical grids, oil pipelines, detecting forest fires, and monitoring other infrastructures. These capabilities also support firefighting efforts by locating and assessing fires, even under poor visibility conditions.

as UAV technology is applied to a broader array of complex tasks, the need for enhanced imaging performance becomes more pronounced. The increase in detector resolution and size, coupled with a decrease in pixel size, presents specific optical challenges.

The trend toward smaller commercial drones further complicates the challenges faced by optical manufacturers.

INNOVATIVE SOLUTIONS: High-quality lenses are crucial for harnessing advancements in detector technology. A subpar lens will yield poor images, irrespective of the detector’s quality. To achieve high performance with small pixel detectors, lower F# values and tighter tolerances are necessary, resulting in lenses with minimal aberrations. Additionally, these lenses must possess long focal lengths to capture images from significant distances. Our approach utilizes advanced folded-optics and lightweight zoom lenses, specifically optimized for next-generation infrared thermal imaging systems.

optical Solutions for UAVs and Drones

Ophir employs cutting-edge technologies to fulfill the optical requirements of UAVs and drones. these solutions encompass innovative optical and mechanical designs, specialized materials, and unique lens manufacturing and coating techniques.

Continuous zoom lenses effectively tackle the low-SWaP challenge while maintaining high optical performance. These lenses are more compact and lighter than using multiple single-field-of-view lenses. Moreover, a continuous zoom lens enhances mission adaptability by allowing for magnification adjustments during UAV operations.

In collaboration with defense and commercial partners,Ophir has developed a series of thermal imaging zoom lenses that are both lightweight and high-performing,tailored for UAV payloads,drones,and handheld devices. The advanced zoom lenses feature a sophisticated optomechanical design, ensuring they are the smallest, lightest, and most compact while achieving superior IR thermal imaging performance.

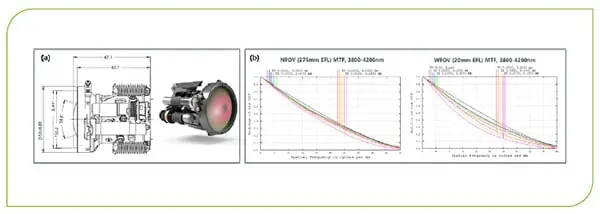

For instance, Figure 2(a) illustrates the LightIR 20-275mm f/5.5 lightweight zoom lens and its opto-mechanical configuration.this innovative design results in a mere weight of 264 grams.Despite stringent SWaP constraints, the advanced lightweight construction achieves high MTF values across the entire field, as depicted in Figure 3(b).Moreover, the selection of advanced materials provides unique athermalization properties, ensuring optimal performance across a wide temperature range of -35°C to +65°C.

The features of this lens enable extended operational ranges relative to its size and weight. Such as, the detection range for a 2.3m vehicle can reach approximately 15km when paired with a 23mK NETD, 15μm pixel detector (based on FLIR92 model calculations). To our knowledge, this is the smallest and lightest continuous zoom lens available today, facilitating the high-performance capabilities of advanced IR thermal imaging systems in challenging environmental conditions and on constrained platforms.

Fig. 2. Lightweight 20-275mm f/5.5 zoom lens

(a) Opto-mechanical layout and image, (b) MTF characteristics

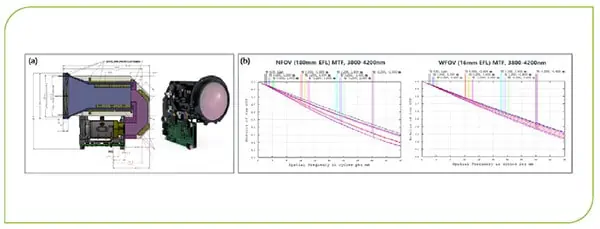

Another strategy to address the low SWaP challenge involves folded-optics configurations specifically designed for compact gimbaled payloads. An example is Ophir’s folded-optic 16-180mm f/3.6 zoom lens, optimized for MWIR 10μm pixel detectors.

Figure 3(a) showcases the opto-mechanical layout and image of the 16-180mm f/3.6 zoom lens. The design employs a standard relay and objective configuration,featuring two moving groups that facilitate focal length adjustments.

Material selection was guided by best practices, incorporating athermalization and achromatization principles.

The folded-optic design allows for extended optical lengths, reducing sensitivity to tolerances in a compact setup, with fewer optical elements, while addressing various challenges inherent to this concept. These challenges include line-of-sight (LOS) stabilization and minimizing the number of optical components, leveraging our capabilities in producing aspheric and diffractive surfaces with remarkable precision and quality.

Fig. 3. Folded-optic 16-180mm f/3.6 zoom lens

(a) Opto-mechanical layout and image, (b) MTF characteristics

figure 3(b) illustrates the MTF results as a function of spatial frequency for the 16-180mm folded design in both wide and narrow fields of view, demonstrating the design’s ability to achieve near-diffraction-limit performance. The high MTF performance is consistent across the entire field, with reasonable performance even at the corners.

Diamond turning technology is frequently employed to create aspheric and diffractive surfaces with exceptional accuracy and quality. Aspheric lens surfaces are particularly advantageous in infrared optics, significantly enhancing optical performance compared to spherical counterparts. Aspheric-diffractive lens surfaces facilitate the integration of multiple functions, such as correcting chromatic and spherical aberrations. Lenses produced through diamond turning can thus combine multiple elements, minimizing overall size and weight.

The request of durable, anti-reflective coatings further enhances optical performance without affecting lens size or weight. These coatings maximize transmission by minimizing reflection losses.Advanced coating techniques can produce custom coatings tailored to the UAV industry, where drones operate in diverse environments, each presenting unique optical challenges.

PRODUCT CAPABILITIES

Ophir’s product range for UAVs, payloads, drones, and handheld devices includes the following features:

- Compact lenses designed for miniature gimbals

- Ultra-lightweight zoom and fixed-focus lenses

- Exceptional optical performance

- Low energy consumption

- High durability (HD) or low-reflection hard carbon (LRHC) AR coatings

- Rapid field of view adjustments

- Continuous zoom with fixed F# maintained throughout the zoom range

- Precise through-zoom bore sighting

- Compatibility with major MWIR and LWIR detectors

- Diffraction-limited optical design

FINAL THOUGHTS: Cutting-edge optical solutions are essential for enhancing airborne mission performance, ensuring high imaging quality without significantly burdening the UAV payload. UAVs and drones equipped with top-tier detectors, image processing software, and displays must also feature high-performance lenses to avoid compromising image quality.

Optics for UAVs and drones must adhere to stringent SWaP (Size, Weight, and Power consumption) constraints. Meeting these demands poses challenges for optical lens manufacturers, who must deliver compact, lightweight, and high-performance lenses capable of functioning in harsh environments.

These challenges are addressed through advanced manufacturing technologies and innovative opto-mechanical designs. Ophir has successfully developed advanced IR zoom lenses with reduced SWaP based on a unique folded-optic design, suitable for 10μm pixel sizes, as well as lightweight opto-mechanical concepts with relatively long focal lengths. Both lens types demonstrate MTF performance approaching the diffraction limit, enabling long-range, high-resolution vision and identification in demanding environmental conditions and on constrained platforms.

Such advanced IR optical assemblies fulfill the rigorous requirements of the UAV industry and pave the way for new opportunities in next-generation UAV and drone thermal imaging applications.

REFERENCES

1. Teal Group (2017)

2.Gettinger, D. (2017). Public Safety Drones. Retrieved from Center for the Study of the Drone