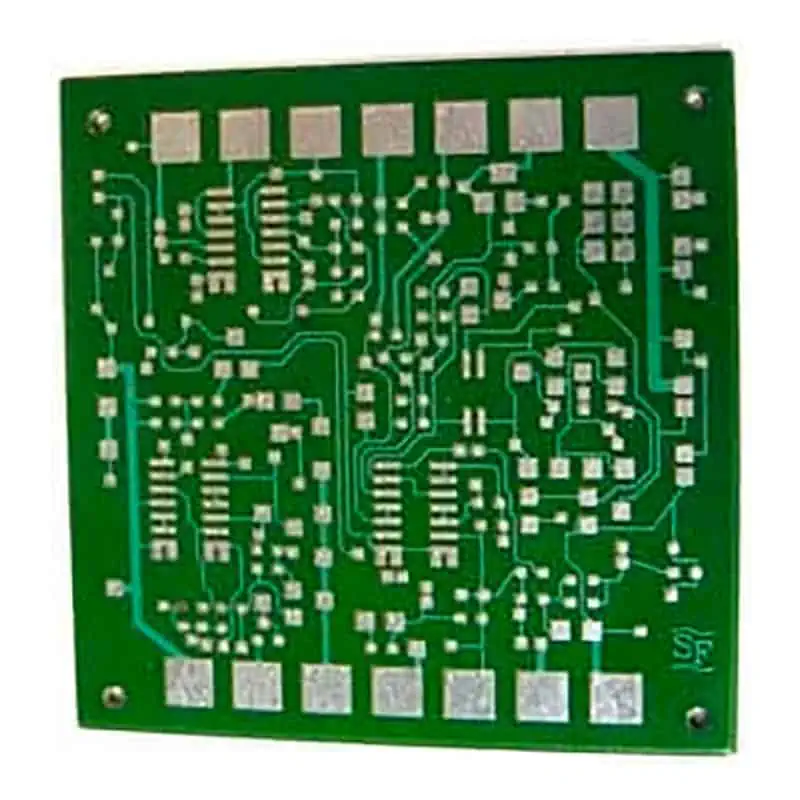

San Francisco Circuits provides both prototype PCBs and large PCB production volumes for every application of unmanned systems utilizing both basic and advanced technologies.

Our team of experienced technical experts strive to provide a quick turnaround, not just on printed circuit boards, but also customer service.

- PCB Fabrication & Assembly

- PCB Board Technology

PCB Fabrication & Manufacturing Capabilities

Printed Circuit Boards for Drones, UAVs, UGVs and Robotics

| Specifications | Standard Technology | Advanced Technology | ||

| Number of Layers | 1 – 12 | 14 – 40 | ||

| PCB Board Material | Rigid PCB Materials FR4 FR406 370HR VT-47 FR408 Arlon CEM Megtron 6 Astra MT77 Tachyon 100G Nelco 4000 Rogers 3000 Series Rogers 4000 Series Rogers 5000 Series Rogers 6000 Series Taconic TLY Polyimide |

MCPCB, Aluminum Core & Copper Core Materials Aluminum Core Copper Core Ventec VT-4A1/VT-4A2 Aismalibar Fastherm Aismalibar Flextherm |

Flex PCB Materials Kapton Shin-Etsu – Epoxy Adhesive System Rogers – Epoxy Adhesive System Dupont FR – FR Acrylic Adhesive System Dupont LF – LF Acrylic Adhesive System Adhesiveless Base Materials |

Aluminum Core Ventec VT-4A1/VT-4A2 Aismalibar Fastherm Aismalibar Flextherm Copper Core Nelco 4000 Rogers 3000 Rogers 4000 Rogers 5000 Rogers 6000 Series Taconic TLY Polyimide |

| Min. Circuit Board Thickness | 2 layer – 0.010″ 4 layer – 0.020″ 6 layer – 0.020″ 8 layer – 0.062″ 10 layer – 0.062″ 12 layer – 0.062″ |

2 layer – 0.005″ 4 layer – 0.010″ 6 layer – 0.031″ 8 layer – 0.040″ |

||

| Max. Circuit Board Thickness | 2 layer – 0.125″ 3-12 layer – 0.200″ |

0.250″ – 0.500″ | ||

| Max. Circuit Board Size | 16″ x 22″ 12″ x 21″ |

10″ x 16″ 16″ x 22″ 12″ x 21″ |

||

| Copper Thickness | 0.5 oz – 3 oz | 4 oz – 10 oz | ||

| Hole Aspect Ratio | 7 : 1 | 15 : 1 | ||

| Min. Hole Size | 0.008″ | 0.004″ | ||

| Min. Trace/Space | 0.006″/0.006″ | 0.002″/0.002″ | ||

| Min. Drill-to-Copper | 0.010″ | 0.005″ | ||

| Min. Pitch | 1 mm | 0.3 mm | ||

| PCB Board Finish | HASL (Solder) Lead Free Solder Copper Gold Gold Fingers White Tin ENEPIG ENIG |

HASL Gold (ENIG/Hard/Soft) Selective Gold Immersion Silver OSP White Tin ENEPIG |

||

PCB Assembly

More: PCB Assembly

Military Grade PCBs (Mil Spec)

More: Mil Grade PCBs

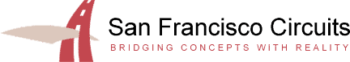

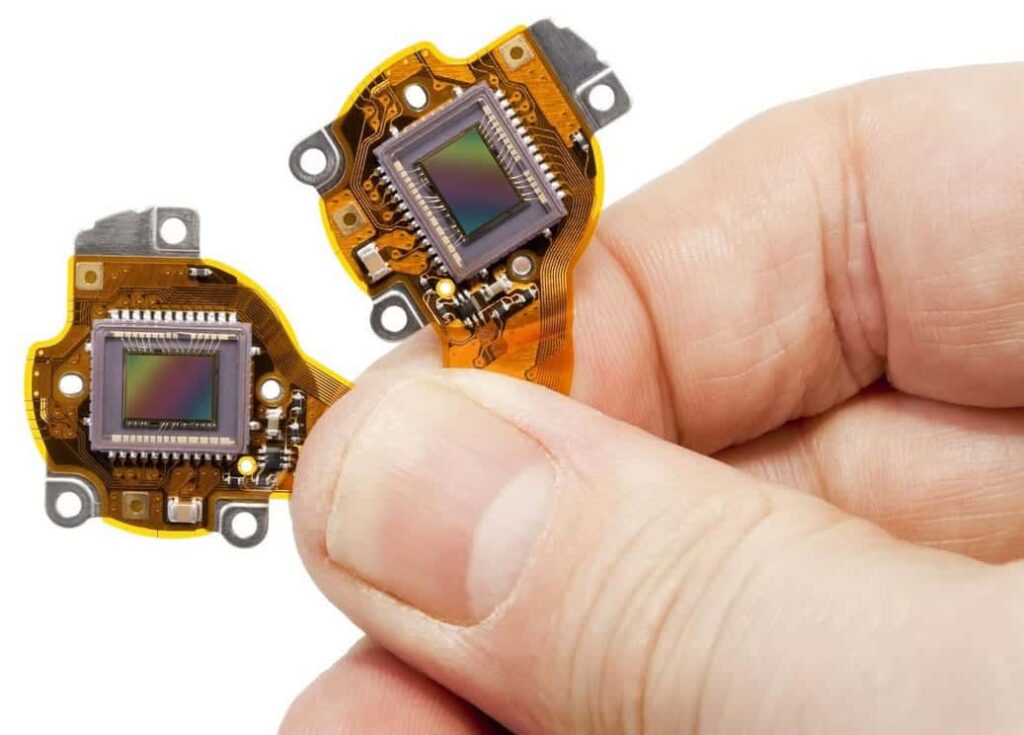

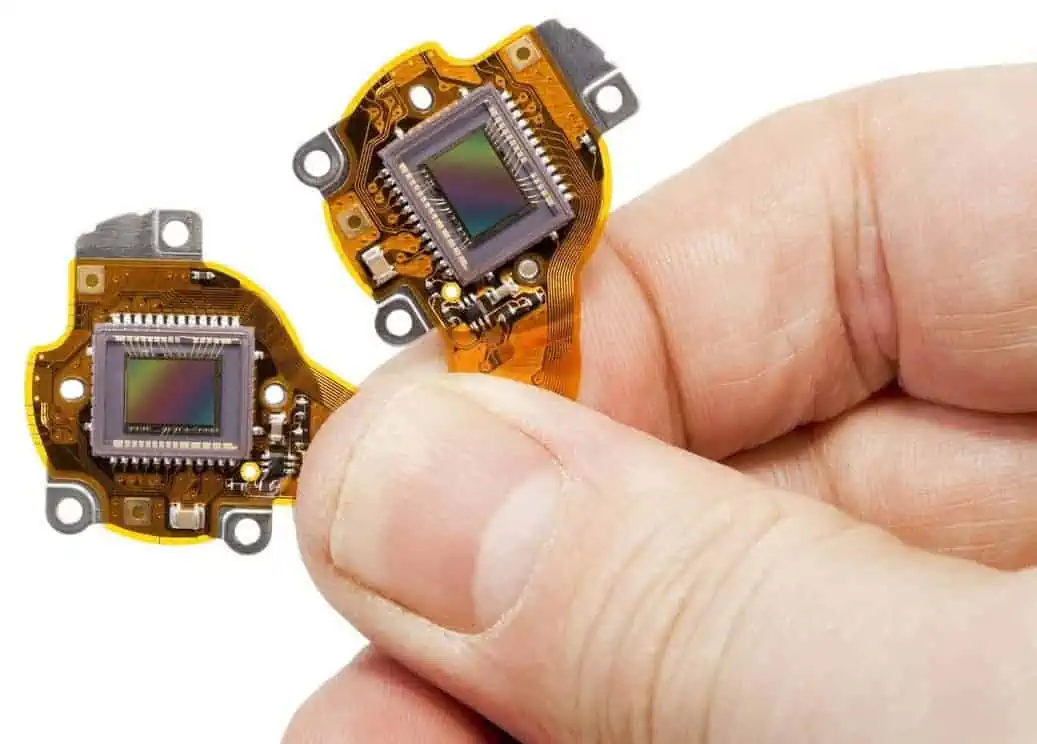

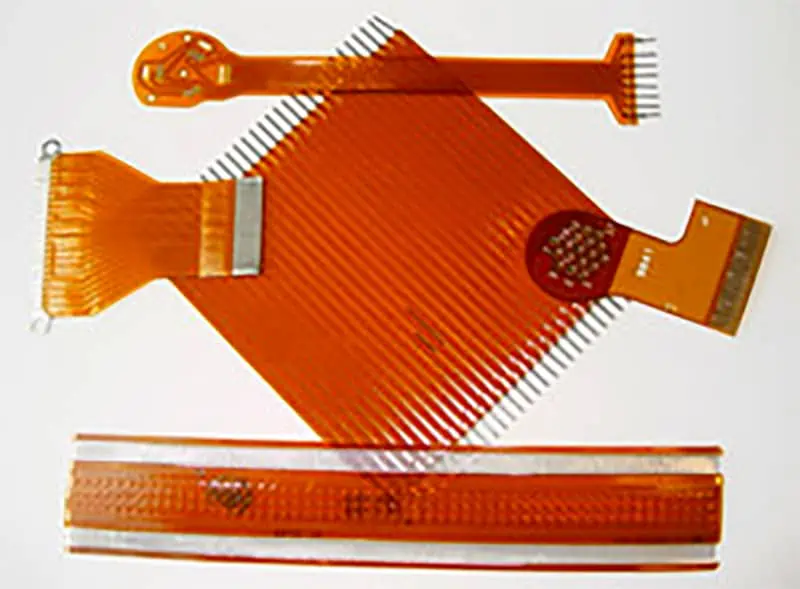

Flex PCBs

We can provide heavy copper Flex PCBs and double-sided multilayer Flex PCBs. Turnaround for your design can be as fast as 24 hours.

More: Flex PCBs

Metal Core PCBs

Metal core PCBs use a base metal such as aluminum, copper or a special alloy to dissipate heat away from sensitive components and other critical parts of the design. This allows heat transfer that is 8 or 9 times faster than in traditional FR4 boards. Metal core PCBs are ideal for applications such as LED lighting, power converters and motor control. We can provide aluminum or heavy copper core PCBs for prototypes or production quantities.

More: Metal Core PCBs

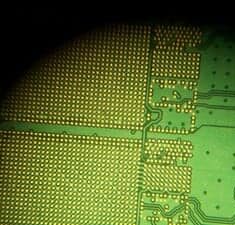

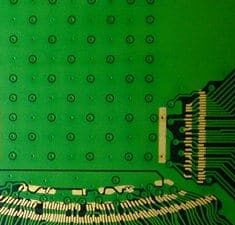

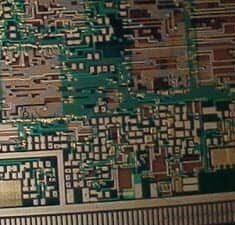

HDI PCB

HDI PCB technology is one of the fastest growing areas of the PCB market. HDI circuits provide much higher wiring densities than standard PCBs, and incorporate features such as blind/buried vias, vias-in-pad and micrometre-level circuit geometries. HDI technology can reduce the size and weight of your boards while enhancing signal transmission and reducing signal loss. We can provide a variety of board construction methods and materials, including flexible HDI PCBs.

-

- 8 Layer Flip Chip

-

- High Density Wirebond Array

-

- Multi Chip Module

More: HDI PCBs

RF PCB Manufacturing

More: RF/Microwave PCB

PCB School

SFC has developed a unique offering for engineers and PCB buyers. The PCB School is a free online resource created to help educate users on various technologies, equipment, and buying resources relating to printed circuit boards.

Find out more: SFC’s PCB School