Sarcos Robotics is at the forefront of developing cutting-edge mobile robots, such as the Guardian® S, which is engineered for remote visual inspections (RVI) in demanding environments.

A recent case study from HZO highlights how their Parylene coatings have effectively shielded the Guardian S from extreme conditions, ensuring dependable performance during critical missions.

The Guardian S robot was designed too endure exposure to liquids and corrosive substances in unpredictable industrial settings. Sarcos required a lightweight yet robust protective solution that would align with the robot’s compact design.

Identifying the challenges

The Guardian S robot encountered important challenges, including the need to function in environments with liquid depths exceeding 2 inches, such as rain, oil, and saltwater.

Conventional mechanical seals were deemed inadequate and overly bulky for the robot’s agile and compact design.Sarcos sought a protective solution that would preserve the robot’s slim profile while ensuring resilience in harsh conditions.

For further insights into HZO’s state-of-the-art ultra-thin conformal coating solutions, access the complete case study on the HZO website >>

HZO’s Conformal Coating Solution

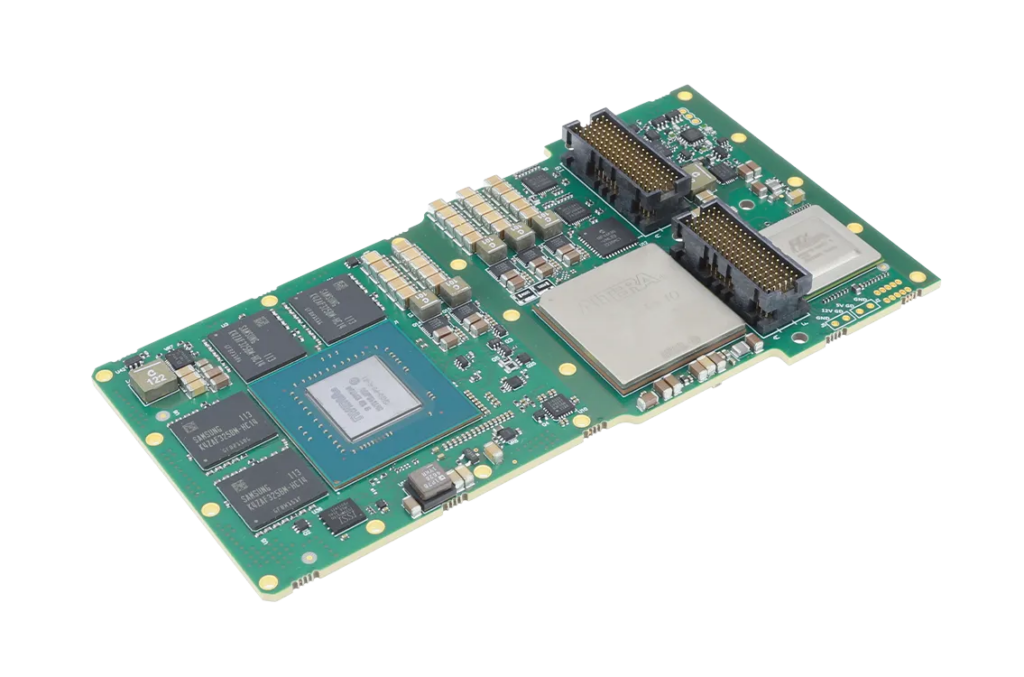

- Parylene Coatings: These coatings offer a lightweight, thin layer of protection without sacrificing functionality.

- IP65 Ingress Protection: Essential for maintaining the robot’s durability in challenging environments, including exposure to oil, saltwater, and cleaning agents.

Design and Development Process

In search of a dependable alternative to mechanical seals, Sarcos reached out to HZO based on a proposal. The design process involved:

- Providing detailed schematics by Sarcos, which outlined specific masking points to ensure accurate coating application.

- Utilizing HZO’s Coating-as-a-Service model, which allowed Sarcos to leverage HZO’s expertise while maintaining an efficient production workflow.

- Collaboration with HZO’s engineers to create a customized coating solution that addressed Sarcos’ unique complexities, process design, and production requirements.

The Parylene Coatings from HZO effectively safeguarded the Guardian S’s electronics, enabling the robot to operate reliably in water depths of up to 2 inches. The coating process utilized advanced masking automation and optimized coating chambers, facilitating scalable application. Sarcos also benefited from HZO’s Coating-as-a-Service model, which ensured precision and quality while seamlessly integrating into their production line.

Access the complete case study on the HZO website >>