Protecting electronic signals from external disruptions is crucial for maintaining reliable operations in autonomous vehicles. Effective shielding becomes particularly vital when operating unmanned systems within electromagnetically noisy environments. In this guide, Nicomatic outlines key strategies for optimizing shield performance on wiring harnesses, emphasizing proven methodologies and industry-leading practices.

Importance of shielding

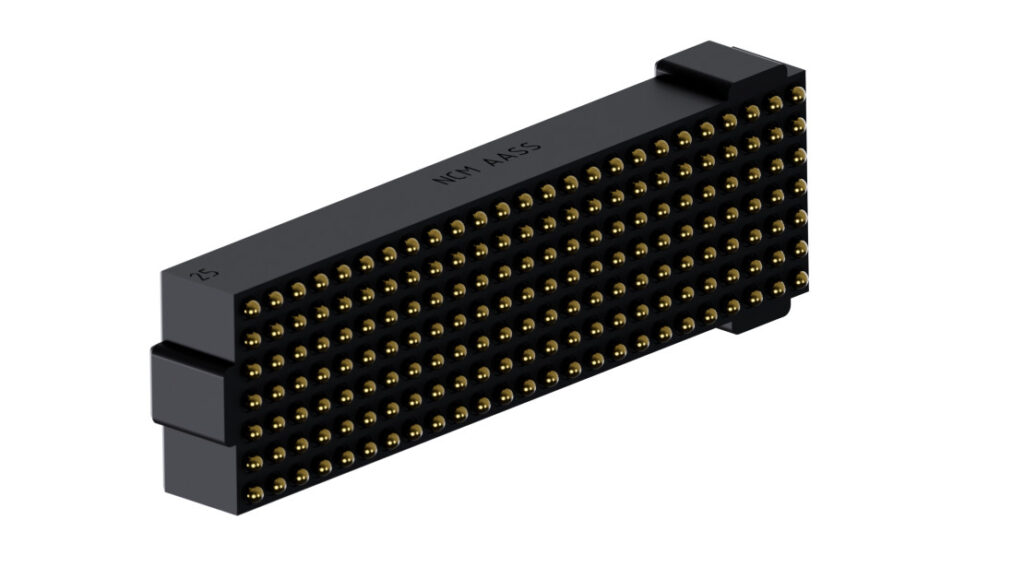

Robust shielding safeguards unmanned system communications against electromagnetic and radio frequency interference (EMI/RFI). Properly implemented protective layers prevent these disturbances from compromising signal integrity. Metallic materials, appropriately grounded through conductive connectors, form the foundation of effective shielding solutions.

Core shielding elements

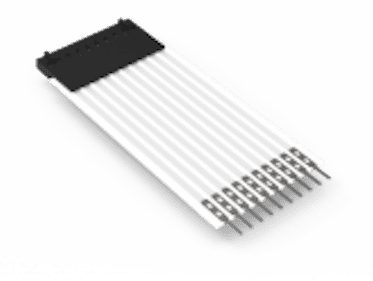

- Conductive braid material selection: Choosing compatible metals for both braid and connector ensures optimal performance.

- Coverage density: High-density braiding maintains shield effectiveness when expanded over cable bundles.

- Proper sizing: Braid diameter must accommodate the underlying wires to guarantee comprehensive protection.

- Metal connector backshell integration: Secure braid attachment to the connector shell via backshell ensures robust, stable connections.

Braid-to-connector attachment techniques

- Employing metallic collars: Recommended for securing braids around connector chimneys, minimizing potential interference entry points.

- Enhancing contact surfaces: Collars should firmly press braids against chimneys. Knurled chimney textures can improve retention.

- Ideal chimney configuration: Circular or oval shapes facilitate better collar fit, ensuring 360-degree contact without gaps.

Verification and quality assurance

- Laboratory evaluation: Validate material choices and techniques through rigorous testing to meet transfer impedance (Zt) and resistance specifications. Zt, calculated as Vin/Iout, measures a cable’s EMI resilience. Conduct specific transfer impedance assessments to guarantee optimal shielding effectiveness. Visual inspections following IPC A620 guidelines help verify overall shield quality.

- Manufacturing oversight: Implement stringent production checks to ensure all harness assemblies meet required standards. IPC guidelines offer valuable reference points for acceptable practices.

Implementing effective shielding on wiring harnesses is essential for protecting unmanned systems’ electronic signals from interference. By adhering to these recommendations, engineers can enhance the reliability and performance of autonomous vehicles operating in challenging electromagnetic environments.

Read the article in full here, or visit the Nicomatic website to find out more.