Understanding Immersion Tin: A Sustainable PCB Surface Finish

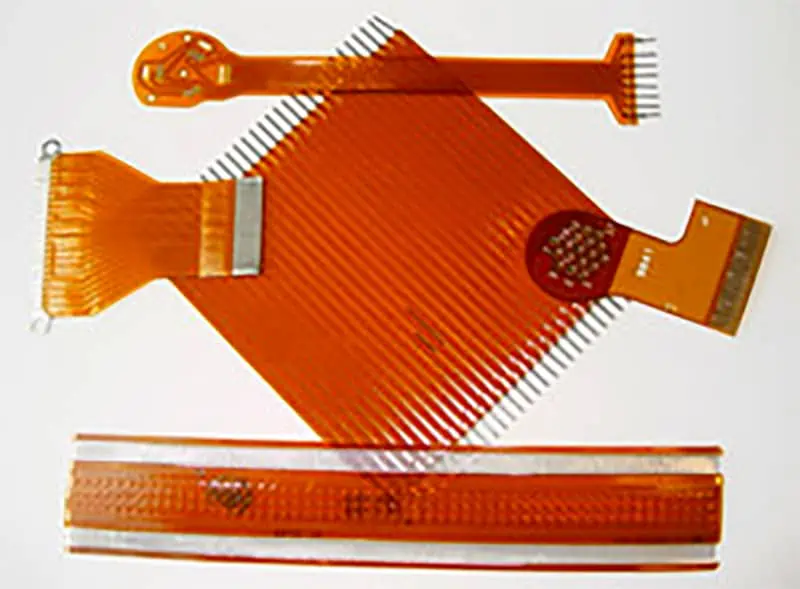

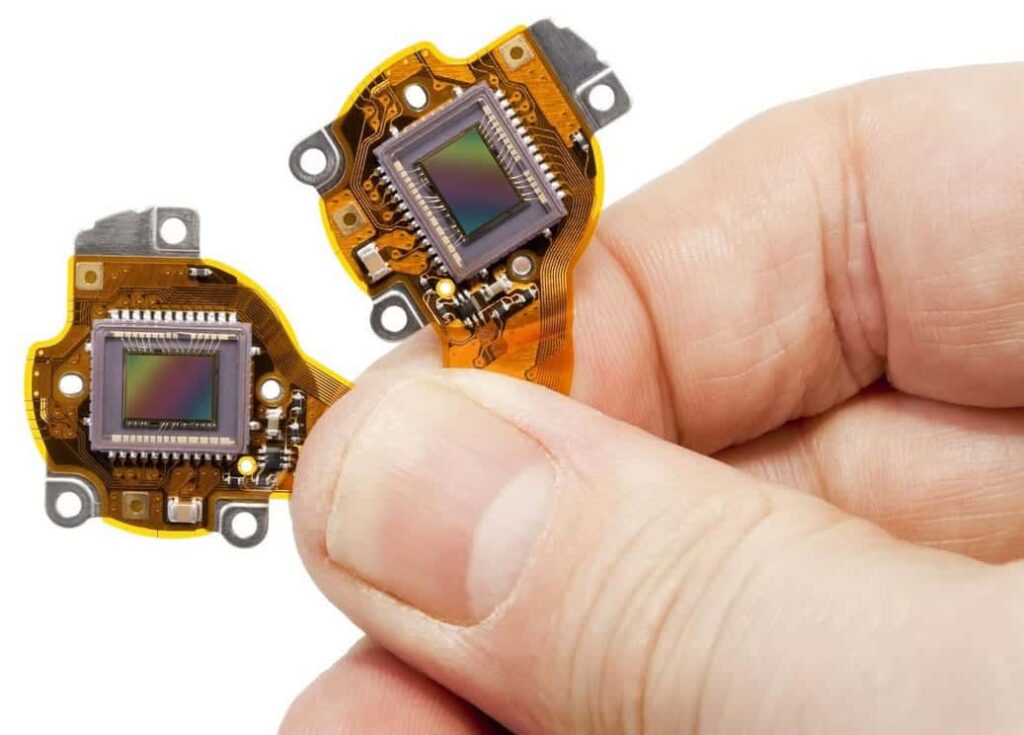

Immersion Tin, commonly referred to as White Tin, is recognized for its compliance with RoHS standards, making it a lead-free option for printed circuit board (PCB) surface finishes. This finish is particularly suited for applications requiring flat surfaces and fine pitch components.

What is Immersion Tin?

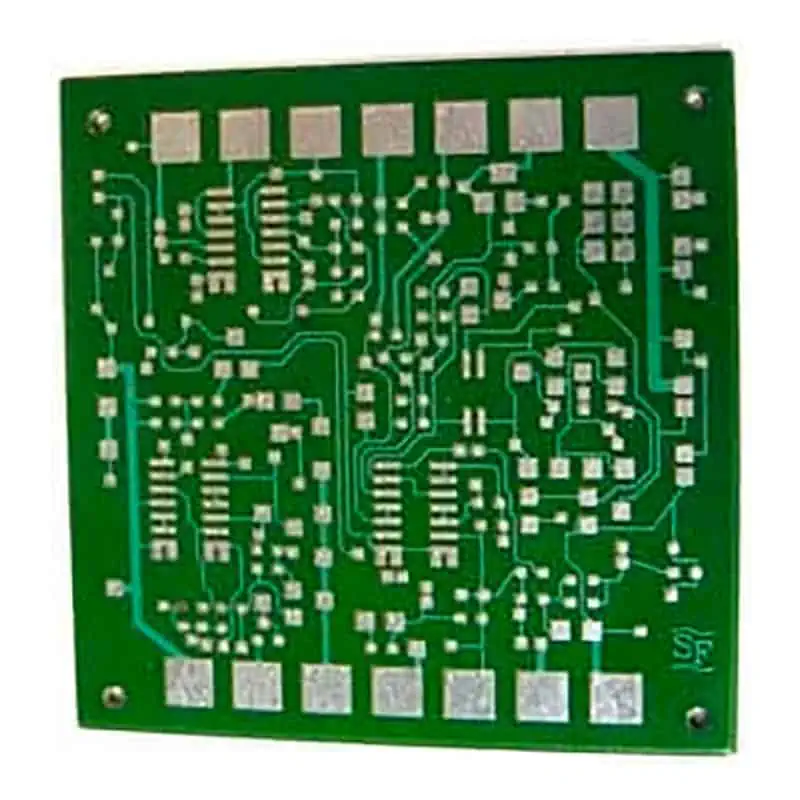

Immersion Tin is a process that involves depositing a thin layer of tin over the copper surface of a PCB. This technique provides remarkable flatness, which is essential for accommodating small geometries and surface mount technology (SMT) components. Additionally, it is indeed one of the most economical immersion coatings available, making it a favored option for projects with budget constraints.

Advantages and Limitations

While Immersion Tin is cost-effective, it does come with certain drawbacks. Its shelf life is relatively short, typically ranging from 3 to 6 months, and it is prone to tin whiskering, which can affect the long-term reliability of the PCB. To ensure optimal performance, careful handling and prompt assembly are essential.

This finish serves as an eco-friendly option to traditional lead-based coatings, requiring fewer resources during its application. its flat surface and reworkability make it particularly suitable for fine pitch components and ball grid array (BGA) assemblies. However, it is not advisable for use in contact switches or applications that demand extended shelf lives.

Comprehensive Solutions from San Francisco Circuits

san Francisco Circuits offers a wide range of PCB fabrication and assembly services,including options featuring Immersion Tin finishes. We cater to various industries, from consumer electronics to telecommunications and high-performance applications, ensuring that our solutions are both high-quality and sustainable, tailored to meet your specific project requirements.

For more data on Immersion Tin PCB surface finishes, visit the San Francisco circuits website.