This case study highlights Mejzlik’s advancement of a two-bladed 30 x 18.7 folding propeller prototype tailored for XSun’s SolarXOne drone, focusing on achieving optimal efficiency at the designated motor speed.

In late 2018, Benjamin David, the CEO and CTO of XSun, reached out to us with a vision for a new drone project. This drone, designed to weigh up to 25 kg and featuring a wingspan of 4.6 meters, would have wings each covering an area of 2.8 m², outfitted with solar panels aimed at maximizing flight duration. benjamin was candid about his goal: to set a world record for the longest uninterrupted flight.

With a rich background from AirBus Defense & Space, XSun is at the forefront of integrating space technology into low-altitude flight. This innovative approach has led to the creation of an autonomous drone powered by solar electric propulsion. Recognizing the challenge ahead, we eagerly accepted the opportunity to collaborate.

The SolarXOne drone features a dual-wing design, meticulously crafted to enhance aerodynamics and overall aircraft performance for extended-range and high-altitude missions. The combination of advanced aerodynamic design and cutting-edge manufacturing techniques results in a highly efficient system that meets the rigorous standards for solar-powered drones.

The project’s objectives were clearly defined, leading to specific requirements for the propeller design at Mejzlik Propellers. The foremost priority was to ensure the propeller’s efficiency to maximize both range and endurance during level flight.

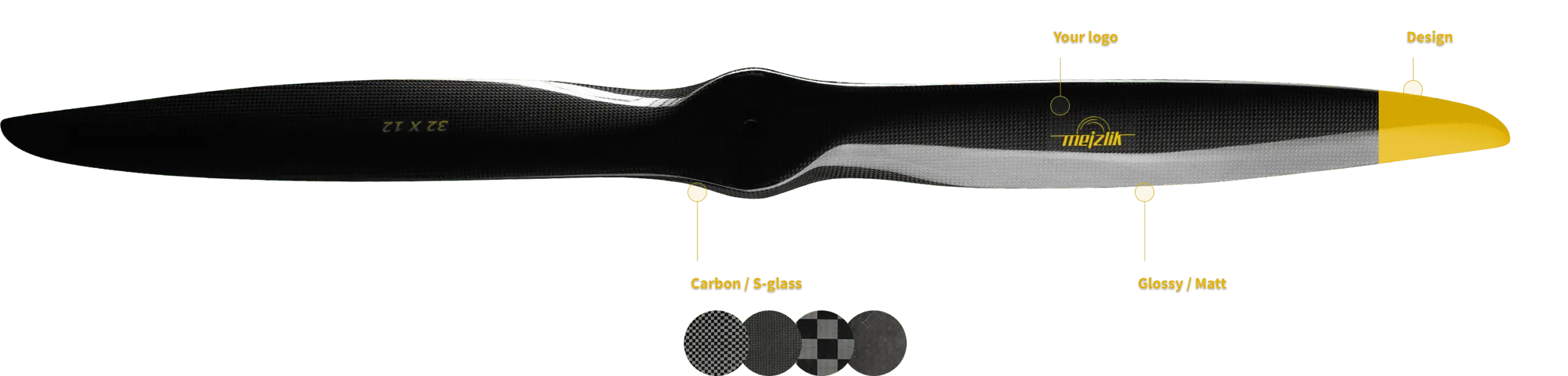

To facilitate belly landings,a folding propeller was essential to reduce drag during the cruise phase. Consequently, Mejzlik Propellers committed to delivering a fully customized propeller tailored to this unique request and aircraft configuration. This propeller would be paired with an appropriate motor to achieve optimal efficiency.

Initially, the specific motor for the drone was not steadfast, complicating the development process as the propeller needed to be optimized for the overall propulsion system’s efficiency.Throughout the project, various motors were evaluated, and extensive testing was conducted. Ultimately, to align with XSun’s specifications, Maxon modified one of its brushless drone motors, the ECX 87 Flat.The focus was on minimizing power consumption while optimizing weight. To meet the stringent efficiency standards, Mejzlik collaborated closely with Maxon, resulting in a propeller optimized for peak efficiency at the target motor speed.This effort culminated in the creation of a two-bladed 30 x 18.7 folding propeller prototype.

The inaugural full test of the propeller and the drone took place in August 2019, marking just eight months sence our initial engagement. The testing yielded positive results, with the client expressing satisfaction: “We are extremely pleased with the propeller.The climbing performance was excellent, there was no vibration, it folded well, and it produced a pleasant sound,” remarked Denis Pitance, the test engineer at XSun.

In July 2020, the solarxone achieved a significant milestone by completing its first long-range solar flight, soaring silently for 12 hours without emitting any CO2 and operating entirely autonomously.

The entire Mejzlik Propellers team celebrated the success of the SolarXOne project,recognizing it as just the beginning. Currently, XSun is testing one of our off-the-shelf propellers for its new SolarXOne.3 project, and we are excited about the upcoming challenge of developing a custom propeller for this initiative.

Insights Gained from the Experience

Interestingly, the highest thrust is not always the primary concern for clients.We increasingly receive requests to enhance propeller performance from the outlook of propulsion system efficiency, specific design requirements, or acoustic characteristics. With the global shift towards renewable energy and the move to emission-free propulsion systems, we anticipate that these factors will become even more critical for our customers. We take pride in demonstrating our ability to meet demanding optimization requirements,as evidenced by our collaboration with XSun and others. A notable benefit of this project was the strengthened partnership with the Maxon Group.