In an exclusive interview with Ultra Motion,defencesource.com explores the distinctive features that position Ultra Motion actuators as prime candidates for unmanned and robotic technologies.

Ultra Motion: Pioneers in Electro-Mechanical Actuation

What makes Ultra Motion actuators particularly effective for unmanned and robotic systems?

The answer lies in our extensive experience and commitment too innovation. With over three decades of expertise in crafting actuators for extreme environments—ranging from aerospace to deep-sea exploration—we have refined our processes and products to excel in the most challenging conditions.

Our servo actuators incorporate Ultra motion’s proprietary Phase Index absolute position feedback system and custom brushless DC motor control electronics. By managing every aspect of design, we ensure a compact and reliable actuator. Manufactured in the USA, our products meet stringent quality standards and can be produced in volumes suitable for drone fleets and swarms.

We continuously adapt to industry needs, focusing on features such as health monitoring, wider temperature tolerances, enhanced power density, minimized backlash, and redundancy.

- Our CAN 2.0B protocol seamlessly integrates with most commercial autopilots and custom flight computers.

- We offer extensive telemetry through CAN and serial interfaces, allowing users to monitor parameters like actuator position, phase currents (indicative of output force), temperature, humidity, bus voltage, and overall system health.

- Actuator travel data is stored in non-volatile memory, akin to an odometer, facilitating preventative maintenance in critical applications.

- Self-heating capabilities enable reliable operation in cold environments.

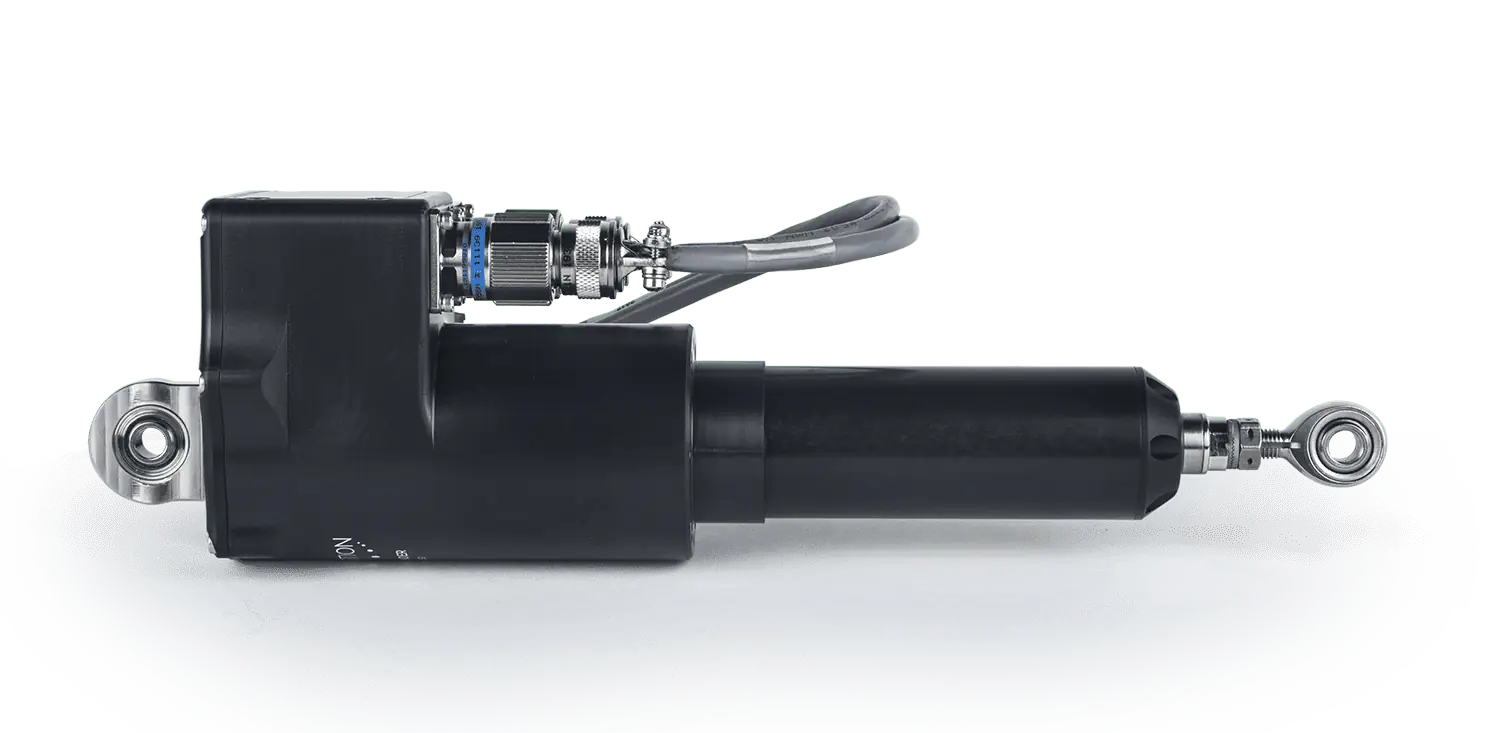

- The new L-Series linear servo features zero axial backlash, enhancing vehicle control authority for high-speed and demanding tasks.

- Additionally, the L-Series can be configured with dual redundancy for applications requiring fault tolerance, such as swashplate actuation and critical payloads.

Advantages of Phase Index Technology in Unmanned Systems

how does Ultra Motion’s Phase Index non-contact position sensing technology enhance your products in the unmanned sector?

In vehicle control scenarios, having absolute position feedback is crucial. Consider a control surface that must reset to a limit switch mid-flight due to an unexpected power interruption. Our Phase Index position sensor delivers high-resolution,battery-free,and contactless absolute position feedback within milliseconds of activation,all in a compact and durable design.

When compared to traditional absolute solutions like potentiometers, LVDTs, and absolute encoders, Phase Index offers numerous benefits. It is indeed resistant to wear and highly durable against shock, vibration, electrical interference, and temperature changes. Additionally, it has minimal impact on the actuator’s size and weight.

For mission-critical applications, dual or triple redundant versions of Phase Index are available, maintaining a negligible effect on size and weight. Further details >>

applications and Design Features of the AM series

What are the typical applications for the AM Series ruggedized servo cylinders, and what design features attract customers?

Ultra Motion Servos are utilized in various uncrewed applications, including:

- Control surfaces, fins, utility actuation, and landing gear for fixed-wing UAVs

- Swashplate and tail-rotor control in UAV rotorcraft

- Rudder, jet-nozzle, and hydrofoil control for USVs

- Throttle, brake, and transmission control in UGVs

- hydroplanes, dive-planes, and sensor deployment in UUVs

- Thrust vector control for small orbital rocket engines

The AM Series is engineered for extreme shock, vibration, and liquid exposure, featuring D38999 connectors, conformally coated control electronics, potted internals, O-ring sealed interfaces, internal humidity control, and a fully conductive enclosure for EMI/EMC compliance. The servo Cylinder’s rapid and precise motion capabilities, combined with high peak force and environmental resistance, make it an ideal choice for dynamic vehicle control.

Building on our experience, Ultra Motion has introduced several new products, including a rotary servo and a high power density linear servo. The L2 linear servo will offer a dual redundant option featuring two motors, two controllers, and a triplicated version of Phase Index for applications requiring electrical fault tolerance and enhanced reliability.

Design Challenges in Marine and Subsea Applications

What challenges arise in designing actuators for marine and subsea applications like ROVs, and how does the AU Series address these issues?

In marine applications, particularly with unmanned surface vehicles, actuators may not be submerged but must endure constant saltwater exposure and significant shock loads from wave action. The primary challenges in marine environments include ingress and corrosion protection, which we tackle through meticulous design and process control.

the AM, AU, T-Series, and L-Series products are equipped with high-pressure O-ring seals on all static ingress points. While this increases manufacturing complexity and quality control demands, O-ring seals significantly enhance ingress protection compared to molded or liquid gaskets. For corrosion resistance, we utilize hard coat anodized aluminum, marine-grade stainless steel alloys, and appropriate dissimilar material isolation to prevent galvanic corrosion. Our process control includes pressure testing for every sealed actuator to ensure seal integrity.

While thoughtful seal design, material selection, and finishing are crucial for preventing liquid ingress and corrosion, internal humidity control is often overlooked. A custom-molded desiccant within the Servo Cylinder exemplifies how Ultra Motion prioritizes long-term reliability in marine environments.

Reliable subsea electric actuation must also contend with hydrostatic pressure that can crush the actuator.Rather of creating an excessively thick-walled enclosure to withstand extreme pressures, our AU actuators utilize a pressure-compensated oil-filled design.This approach employs an incompressible fluid that works with our built-in pressure compensator to equalize pressure differentials, reducing stress on seals and allowing smooth actuator movement against high pressures. Integrating the pressure compensator directly into the actuator simplifies the system by eliminating the need for external components, while the integrated motor controller is designed to withstand extreme pressures at depths exceeding 6000 meters.

customization and Adaptation at Ultra Motion

How does Ultra Motion approach product customization to meet specific customer needs, and can you provide examples of real-world applications?

At Ultra Motion, customizing standard products is a routine practice. Our engineering team collaborates closely with clients to develop specifications, design tailored solutions, and assign custom revision-controlled part numbers. Modifications can range from simple pinout or connector adjustments to entirely new designs that meet specific mounting, redundancy, and performance requirements.