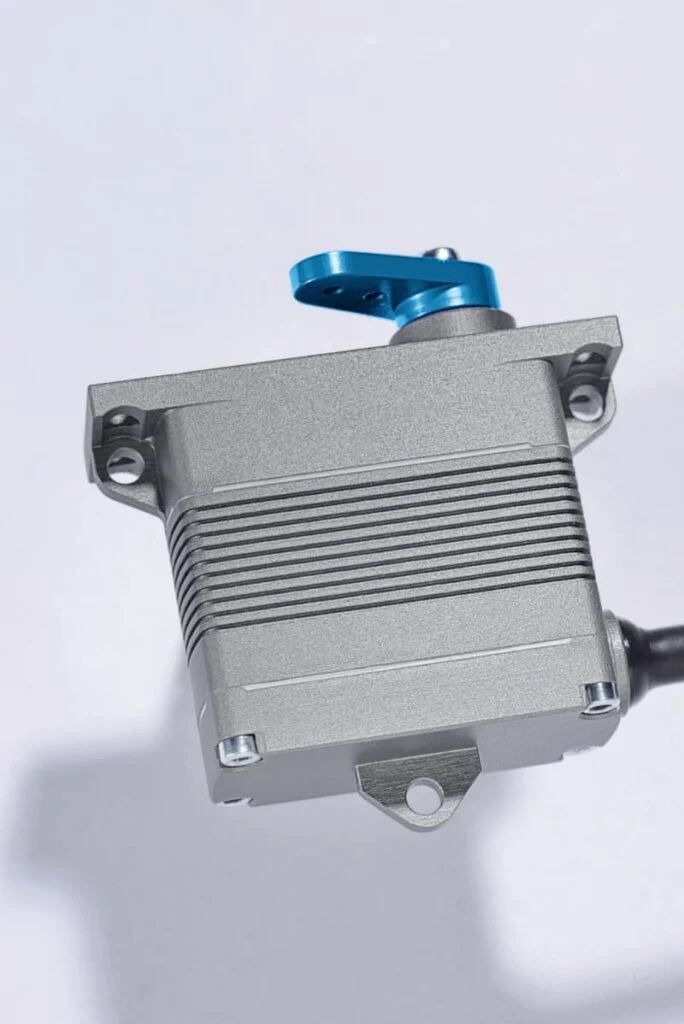

Enhanced Safety and Performance with the DA 30

For optimal safety and dependability, the DA 30 is equipped with a brushless motor alongside a non-contact, wear-free position sensor. This innovative design ensures an extended service life while delivering maximum power output.Additionally, it effectively mitigates electromagnetic interference (EMI) that can arise from brush sparking. Constructed from saltwater-resistant aluminum and treated with HART-coating, the housing complies with the IP-67 standard for water and dust protection.It also features an integrated Sub-D connector, with options for a MIL-spec circular connector or cable gland upon request. The housing includes built-in brackets for both horizontal and vertical installation, complemented by an 8-fold, ball-bearing supported steel gear train and an ANSI multi-tooth drive shaft.

Versatile Input Options for the DA 30 Series

The DA 30 series offers flexibility with a standard Pulse Width Modulation (PWM) input, featuring two distinct interfaces: a differential, galvanically isolated interface (Opto-coupler) and a single-ended interface utilizing CMOS levels, which is also employed for programming servo parameters. This system includes analog position feedback to accurately monitor the position of the drive shaft. Alternatively, users can opt for a differential RS-422 PWM interface instead of the opto-coupled version.

Advanced Digital Interaction and Diagnostics

The DA 30 model, equipped with a digital serial command interface (RS-485), processes commands through a CRC-secured protocol. It not only provides the shaft position in a digital format but also transmits various diagnostic data, including supply voltage levels, current consumption, and the temperature of both the motor and electronics. Optionally, it can also report humidity levels within the actuator casing. These diagnostic features are invaluable for assessing the operational health of the actuators before, during, and after their deployment.