Specialty Coating Systems emphasizes the benefits of Parylene conformal coatings in bolstering the durability of products designed for extreme conditions.

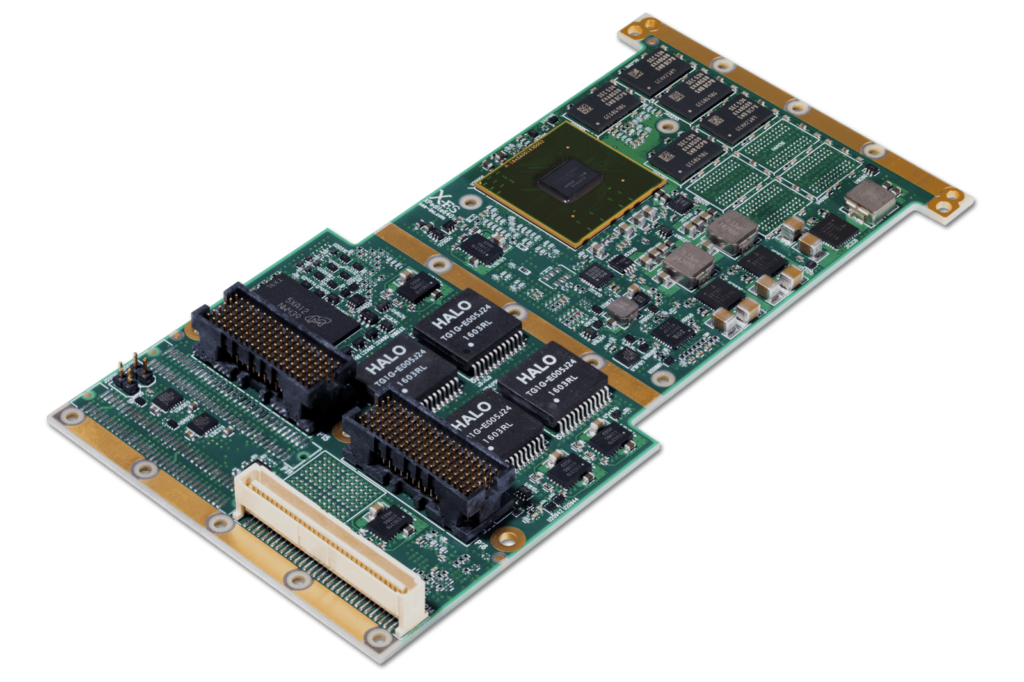

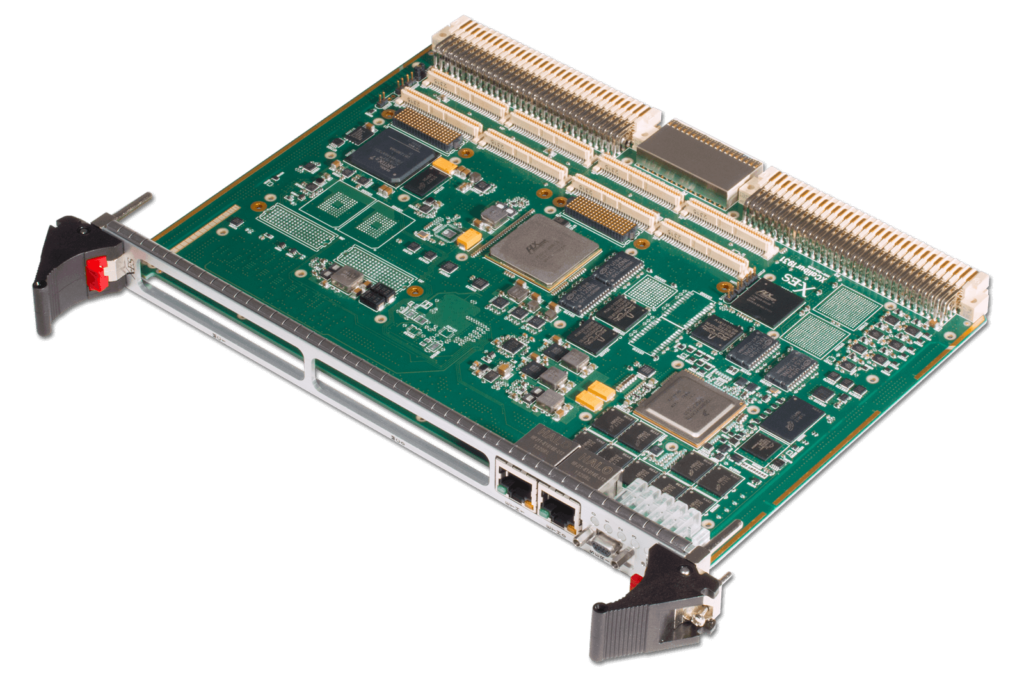

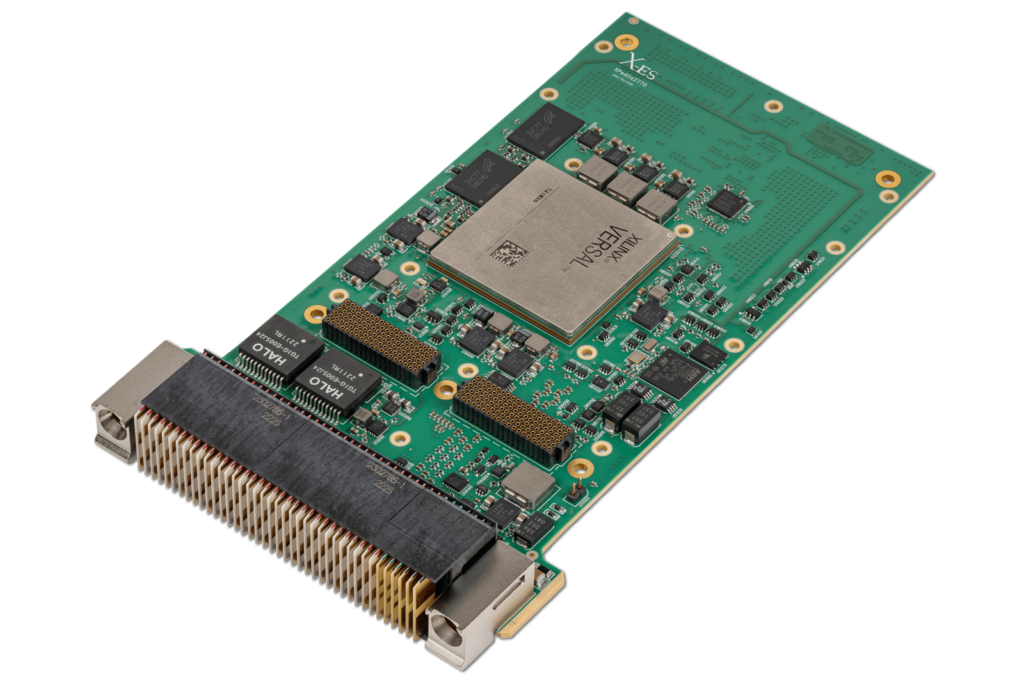

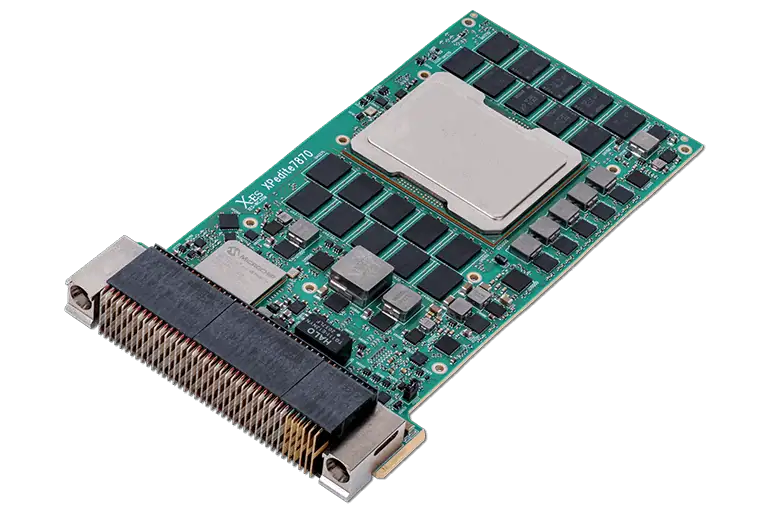

Equipment designed for rugged environments is meticulously crafted to perform reliably under the most challenging circumstances. This includes embedded systems for military use, mobile devices for specialized research, and aerospace components, all engineered to withstand high humidity, extreme dryness, severe temperature fluctuations, intense vibrations, strong winds, and even vacuum conditions. Both the outer casings and internal components are fortified to adhere to stringent durability criteria.

The Role of Parylene Coatings in Enhancing Durability

Manufacturers employ various methods to achieve ruggedization, but Parylene conformal coatings stand out due to their superior performance.These coatings provide remarkable resistance to physical shocks,continuous vibrations,and harsh environmental conditions. They protect against moisture, heat, dust, corrosive chemicals, and other harmful substances. With remarkable dielectric strength and the capability to be applied in ultra-thin layers,Parylene is ideal for a wide array of applications across different industries.

utilization of Ruggedized Technologies

In both military and industrial environments, keyboards and keypads frequently utilize Parylene coatings to safeguard their Printed Circuit boards (PCBs) and other critical components. These coatings enable the equipment to endure rapid accelerations, pressure variations, temperature and humidity changes, impacts, and prolonged vibrations. They also meet MIL-STD-461 standards for electromagnetic interference shielding.

Rugged smartphones, tablets, and similar mobile devices employ Parylene coatings to protect sensitive electronics from dust, moisture, shocks, drops, and extreme temperatures. This ensures reliable connectivity and performance even in adverse conditions. Other ruggedized products, such as cameras, connectors, and bonding assemblies, also gain from this protective layer.

In the automotive sector,sensors,control systems,and seals are ofen subjected to harsh operational conditions. Ruggedization enhances their reliability by minimizing the risk of failure due to thermal variations or exposure to corrosive elements. Parylene is crucial in safeguarding these components, ensuring dependable systems for GPS, WiFi/Bluetooth, and vehicle diagnostics.

The aerospace and commercial industries also depend on Parylene coatings. These coatings prevent unwanted adhesion on silicon-based materials, facilitate reliable fiber optic communication, and protect transceivers and testing equipment from environmental hazards. Applications in these sectors often require adherence to strict standards such as MIL-STD-883,MIL-STD-810,and ARINC 801-806,all of which are supported by Parylene.

Final Thoughts

As the demand for ruggedized systems increases across various sectors, the necessity for products that maintain consistent performance in extreme conditions continues to rise. Parylene conformal coatings offer an effective solution to meet these challenges,enhancing the durability,reliability,and operational lifespan of ruggedized devices and systems.

Read the original article >>