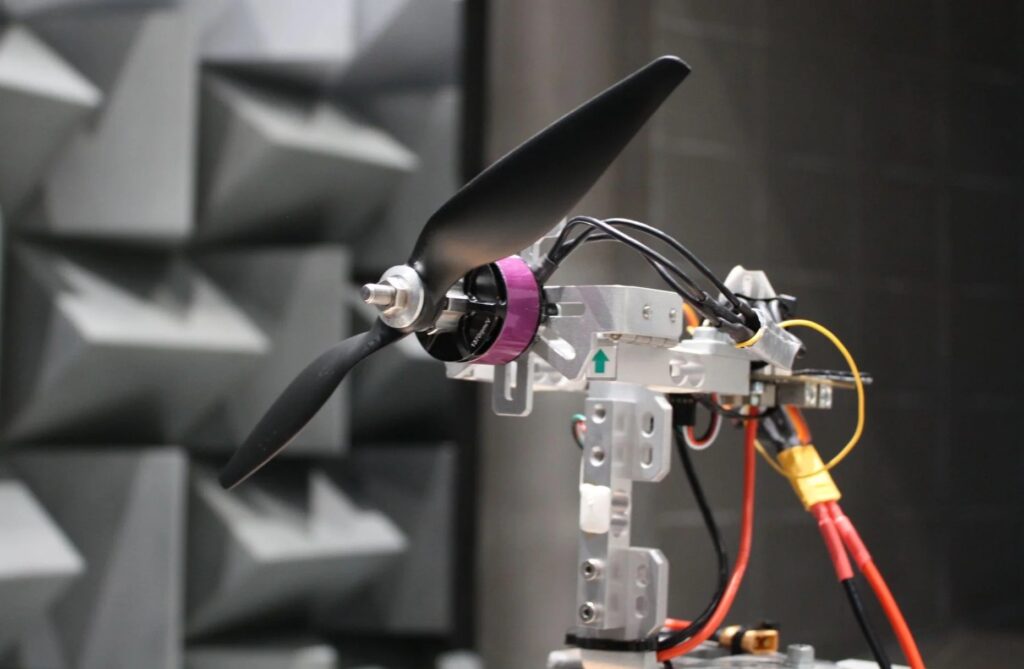

3D printed UAV rotor on a thrust stand by Tyto Robotics.

Exploring the Potential of 3D Printed UAV Rotors

Tyto Robotics investigates the feasibility of 3D printed UAV rotors,questioning whether their noise levels and aerodynamic efficiency can match those of conventional plastic rotors.

Research Initiative and Methodology

Supported by the Nederlands Lucht- en Ruimtevaartcentrum Living Lab, researchers utilized Tyto Robotics’ Series 1585 thrust stand too delve into the capabilities of 3D-printed UAV rotors.The study aimed to compare the aerodynamic and acoustic characteristics of these innovative rotors against conventional propellers, thereby evaluating the technology’s practicality.

Performance Assessment with the series 1585 Thrust Stand

The Series 1585 thrust stand played a crucial role in assessing rotor performance metrics such as thrust,torque,RPM,power output,and overall efficiency. A reference plastic propeller was meticulously 3D scanned and produced using PLA material through an FDM 3D printing process. Even though attempts where made to incorporate fiber-reinforced printing,the resulting thicker lines compromised the quality of the trailing edge,negatively impacting both performance and noise levels.

3D printed rotor on a Tyto Robotics thrust stand in a wind tunnel.

impact of Surface Roughness on Performance

Prior to refining the surface of the 3D printed propeller, an initial performance evaluation was conducted without measuring acoustics. The roughness of the surface significantly influenced thrust output, aligning with expectations for blades operating at low Reynolds numbers.

Advanced Testing in Controlled Environments

Following the smoothing process, both the original and 3D-printed rotors underwent testing in the anechoic chamber of NLR’s Aeroacoustic Wind Tunnel. the comparative analysis revealed that both rotor types exhibited comparable aerodynamic and aero-acoustic performance. This finding indicates that 3D printed propellers could serve as valuable tools for validating and experimenting with intricate rotor blade designs aimed at minimizing noise in small UAVs.

For further insights, visit the Tyto Robotics website or explore additional resources here.