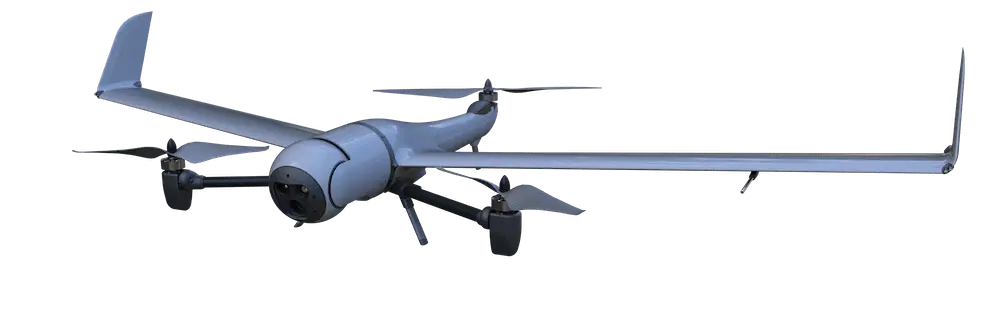

Meller Optics, Inc. has unveiled a range of custom-engineered sapphire lenses, windows, and domes designed to accommodate various features such as bevels, chamfers, flats, grooves, holes, radii, steps, wedges, and more. These products are notably suited for use in unmanned systems, including UAVs, UUVs, and drones, as well as in aerospace, military applications, and machine inspection.

The meller custom Sapphire Optics are specifically crafted for scenarios that demand durable lenses, windows, or domes capable of transmitting wavelengths from ultraviolet to infrared (270 nm to 4.7 µm).

With a Mohs hardness rating of 9, making them nearly as hard as diamonds, these optics can be designed with polished radii to mitigate stress, chipping, and cracking. They can also incorporate various features such as bevels, chamfers, flats, grooves, holes, radii, steps, and wedges with precision tolerances of 6.5º ±1 minute.

Manufactured according to OEM standards, Meller Custom Sapphire Optics can achieve tolerances of ±0.002” on specialized features, depending on the configuration. Major surfaces can be polished to a scratch-dig rating of 10-5, with surface roughness maintained at ≤0.3 rm RA, and flatness controlled to 0.5 fringes hene.