San francisco Circuits (SFC) specializes in providing rigid flex printed circuit board (PCB) solutions, boasting rapid turnaround times of as little as 48 hours, all sourced from reputable manufacturers.

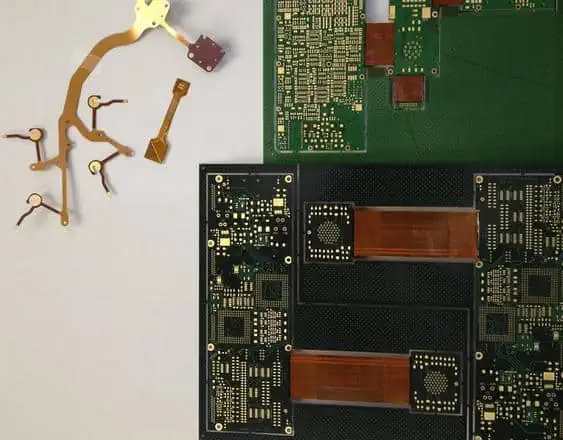

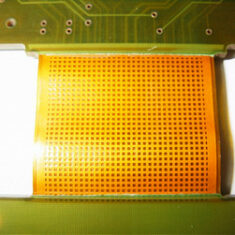

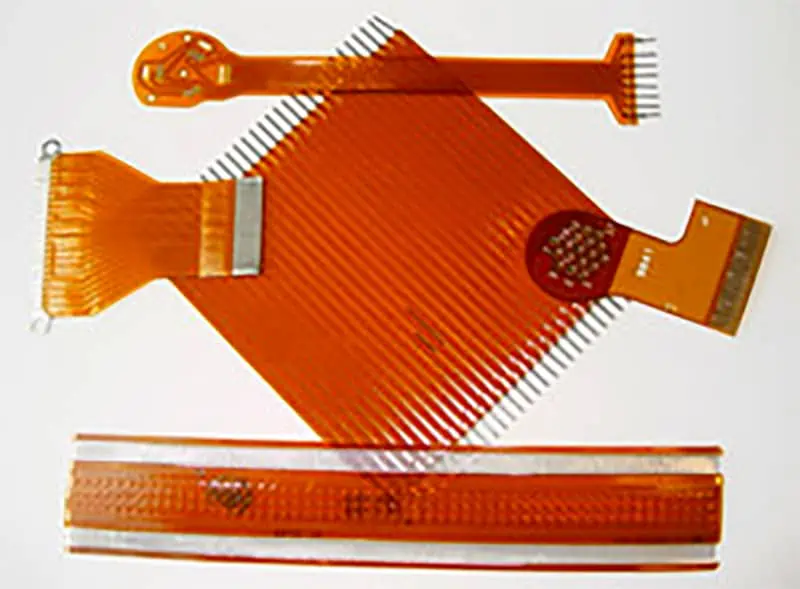

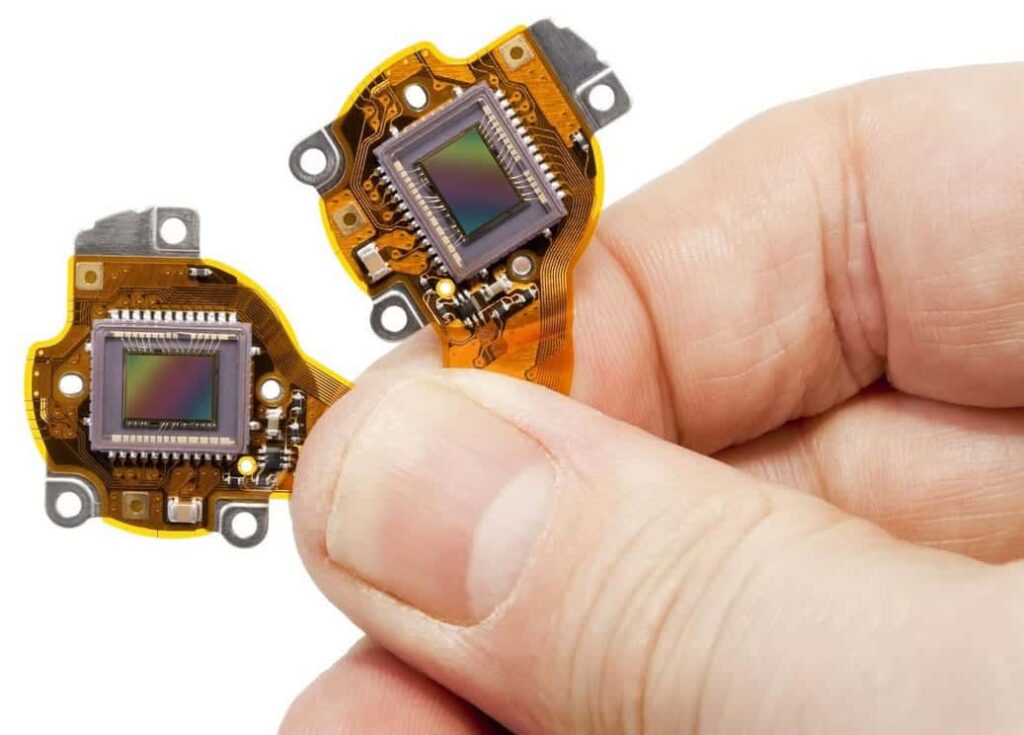

Rigid flex PCBs are composed of several layers of flexible materials bonded to one or more rigid substrates. These flexible layers are engineered to maintain a constant state of flexibility. This innovative design enables engineers to develop circuit board layouts in three-dimensional configurations, enhancing operational efficiency. It reduces teh need for solder joints, connectors, and delicate wiring, thereby facilitating a better fit within the confines of the request’s housing.

SFC is equipped to deliver rigid flex PCBs tailored for critical applications in drones and robotics, including systems utilized by the military.

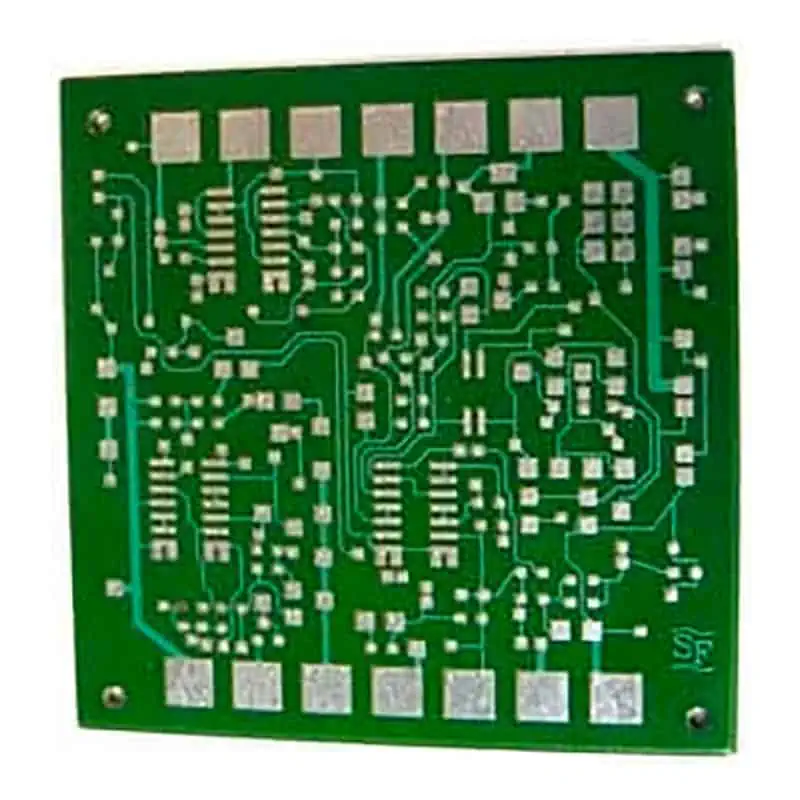

| Specifications | Capabilities |

| Drill to copper – Outer layers | 8 mil |

| Drill to copper – Inner layers | 10 mil |

| Copper Thickness | 0.5 oz – 4 oz |

| Minimum Hole Size | 0.004″ |

| Minimum trace/Space | 0.003″/0.003″ |

| Minimum Pitch | 0.5 mm |

| Copper to board edge | 0.007″ |

| Coverlay Opening | 0.003″ |

| Coverlay Web (Kapton) | 0.006″ |