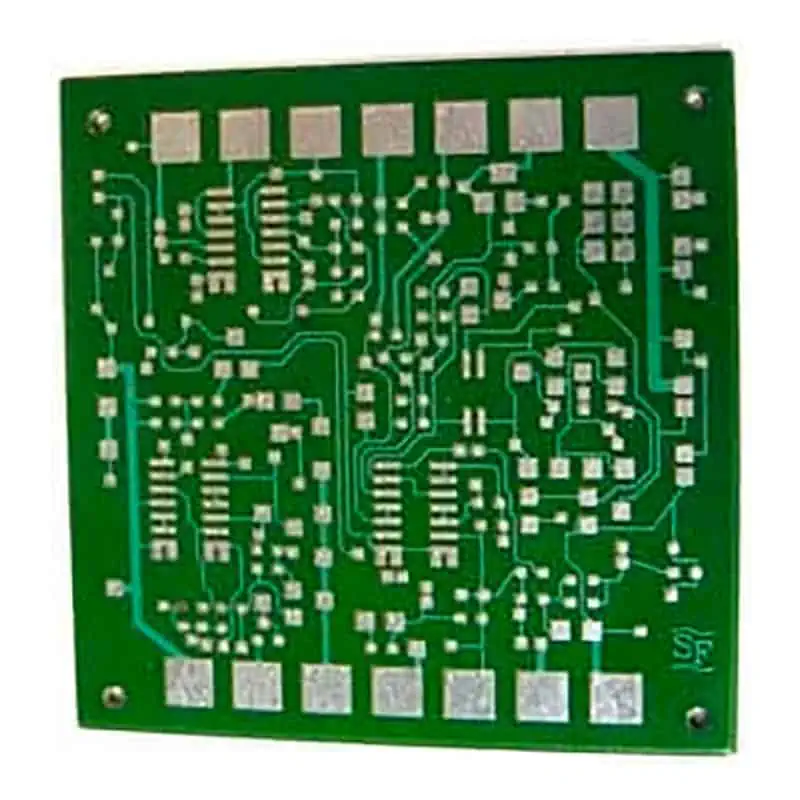

San Francisco Circuits stands at the forefront of PCB manufacturing and assembly.

Our extensive network of PCB manufacturers and assembly facilities, both local and international, enables us to deliver extensive solutions and exceptional value for all your printed circuit board needs.

San Francisco Circuits specializes in both prototype PCBs and large-scale production for various unmanned systems,employing both fundamental and cutting-edge technologies. Our dedicated team of technical professionals is committed to providing rapid responses, not only for printed circuit boards but also for customer support.

Navigate to Section:

-

PCB Fabrication & Assembly

-

PCB Technology

PCB Fabrication & Manufacturing Expertise

Printed Circuit Boards for Drones, UAVs, UGVs, and Robotics

| Specifications | Standard Technology | Advanced Technology | ||

| Layer Count | 1 – 12 | 14 – 40 | ||

| PCB Material | rigid PCB Materials FR4, FR406, 370HR, VT-47, FR408, Arlon, CEM, Megtron 6, Astra MT77, Tachyon 100G, Nelco 4000, Rogers 3000 Series, Rogers 4000 series, Rogers 5000 Series, Rogers 6000 Series, taconic TLY, Polyimide | MCPCB, Aluminum & Copper Core Materials Aluminum Core, Copper Core, Ventec VT-4A1/VT-4A2, Aismalibar Fastherm, Aismalibar Flextherm | Flex PCB Materials Kapton, Shin-Etsu – Epoxy, Adhesive System, Rogers – Epoxy, Dupont FR – FR Acrylic, Dupont LF – LF Acrylic, Adhesiveless Base Materials | Aluminum Core, Ventec VT-4A1/VT-4A2, Aismalibar Fastherm, Aismalibar Flextherm, Copper Core, Nelco 4000, Rogers 3000, Rogers 4000, Rogers 5000, Rogers 6000 Series, Taconic TLY, Polyimide |

| Minimum Board Thickness | 2 layer – 0.010″, 4 layer – 0.020″, 6 layer – 0.020″, 8 layer – 0.062″, 10 layer – 0.062″, 12 layer – 0.062″ | 2 layer – 0.005″,4 layer – 0.010″, 6 layer – 0.031″, 8 layer – 0.040″ | ||

| Maximum Board Thickness | 2 layer – 0.125″, 3-12 layer – 0.200″ | 0.250″ – 0.500″ | ||

| Maximum board Size | 16″ x 22″, 12″ x 21″ | 10″ x 16″, 16″ x 22″, 12″ x 21″ | ||

| Copper Thickness | 0.5 oz – 3 oz | 4 oz – 10 oz | ||

| Hole Aspect Ratio | 7 : 1 | 15 : 1 | ||

| Minimum Hole Size | 0.008″ | 0.004″ | ||

| Minimum Trace/Space | 0.006″/0.006″ | 0.002″/0.002″ | ||

| Minimum Drill-to-Copper | 0.010″ | 0.005″ | ||

| minimum Pitch | 1 mm | 0.3 mm | ||

| PCB Finish | HASL (Solder), Lead Free Solder, Copper, Gold, Gold Fingers, White Tin, ENEPIG, ENIG | HASL, Gold (ENIG/Hard/Soft), Selective Gold, immersion Silver, OSP, White Tin, ENEPIG | ||

More: PCB fabrication Capabilities

PCB Assembly Services

We provide a comprehensive service for all your printed circuit board assembly requirements, managing the complexities of component sourcing and vendor communication. Our assembly services include rapid prototype, turnkey, partial turnkey, consignment, and lead-free assembly options. Typical lead times range from 1 to 5 days for assembly, with or without turnkey services. More: PCB Assembly

PCB Technology Innovations

Military-Grade PCBs (Mil Spec)

Our certified military-grade PCBs are a key focus at SFC. With manufacturing capabilities based in the U.S., we produce reliable, high-quality MilSpec certified flexible or rigid circuits. Our manufacturing adheres to standards such as MIL-PRF-55110, MIL-PRF-50884, and MIL-PRF-31032, offering a variety of finishes, solder masks, silk screens, and fabrication techniques. More: Mil Grade PCBs

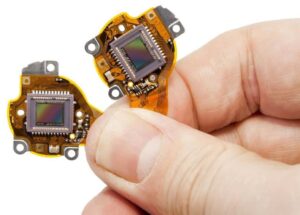

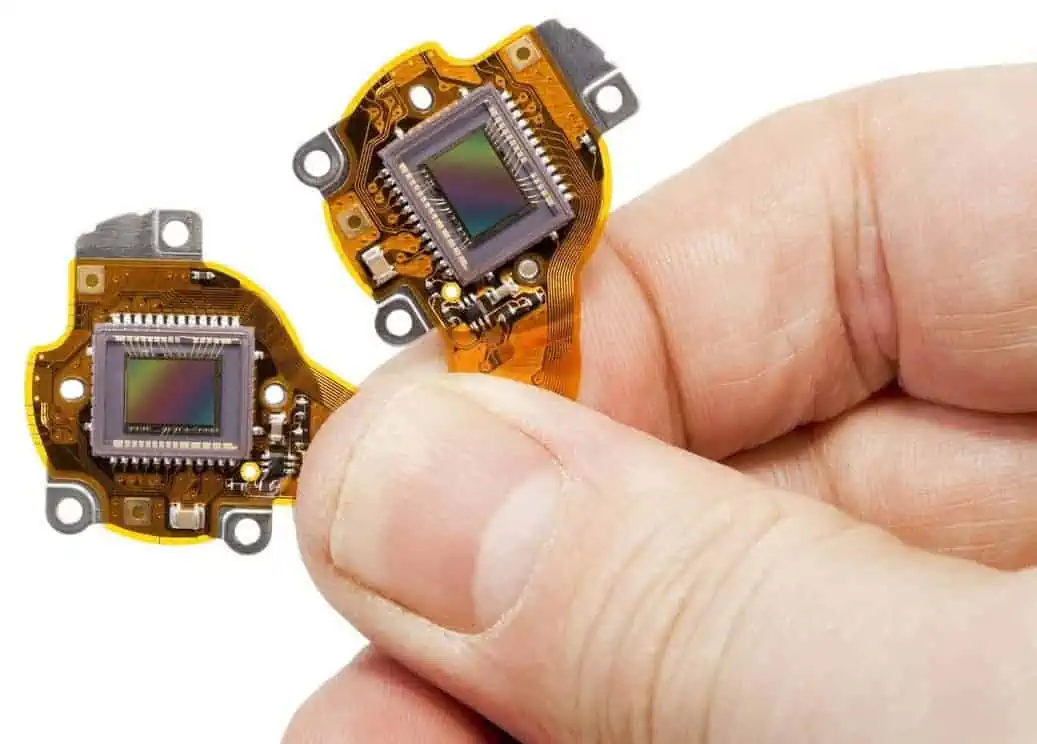

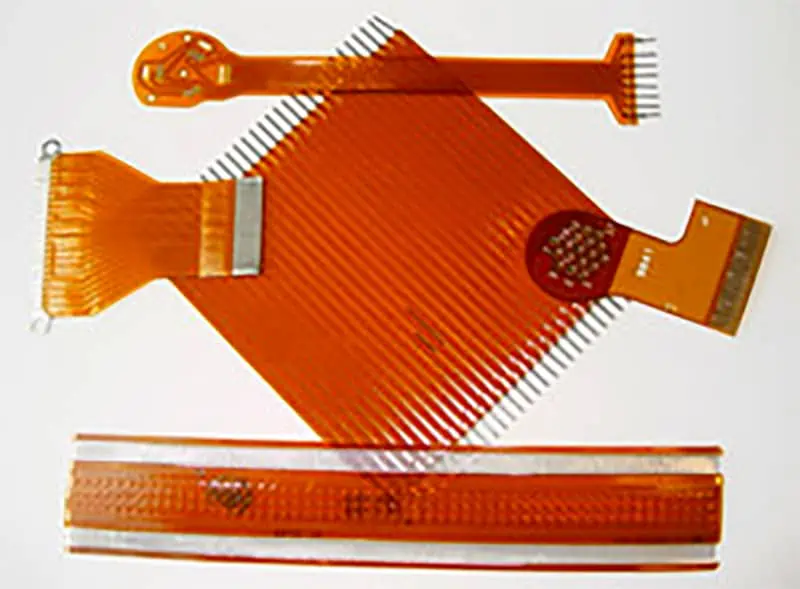

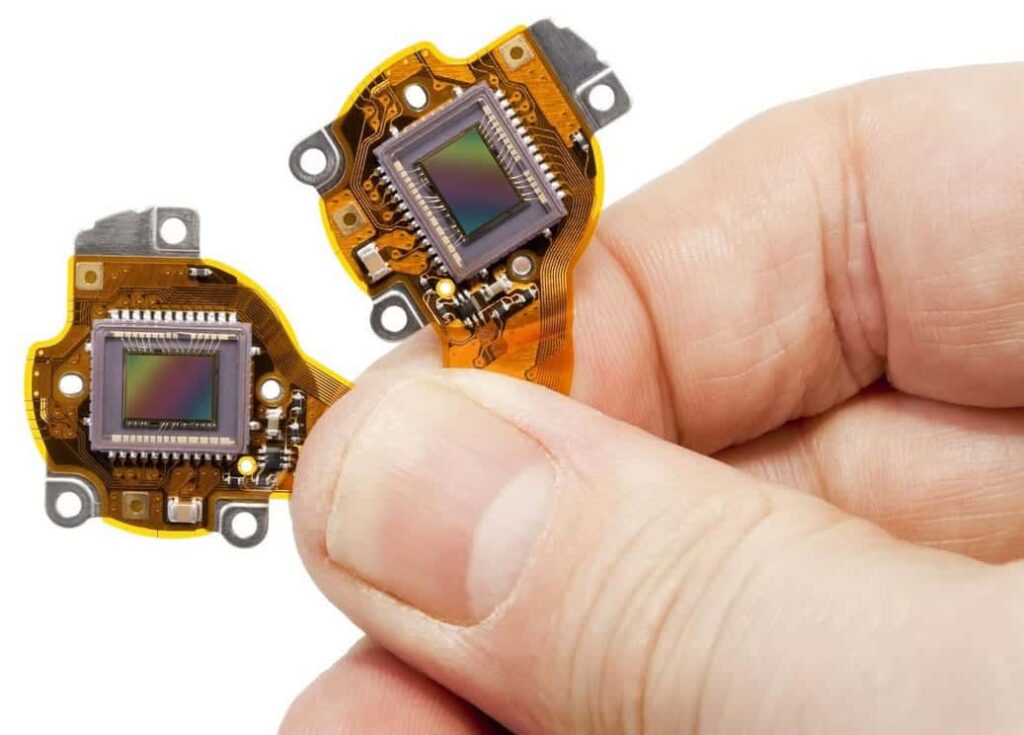

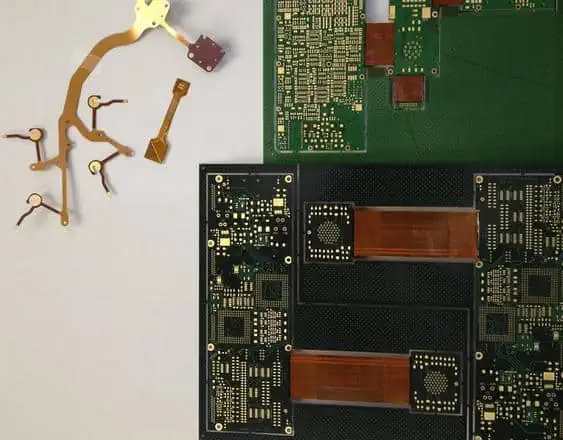

Flexible PCBs

Flexible pcbs utilize the same components as rigid boards but are produced on a flexible substrate, allowing for a variety of shapes. Their reduced size and weight, along with enhanced resistance to noise and vibration, make them ideal for applications in Transportation, Communications, Aerospace, and Unmanned Vehicle Systems. We can deliver heavy copper Flex PCBs and double-sided multilayer flex PCBs, with design turnaround times as swift as 24 hours. More: Flexible PCBs

Metal Core PCBs

Metal core PCBs utilize a metallic base such as aluminum or copper to effectively dissipate heat from sensitive components and critical design areas. This allows for heat transfer that is substantially faster than traditional FR4 boards, making them suitable for applications like LED lighting, power converters, and motor control. We can supply aluminum or heavy copper core PCBs for both prototypes and production runs. More: Metal Core PCBs

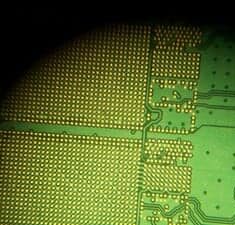

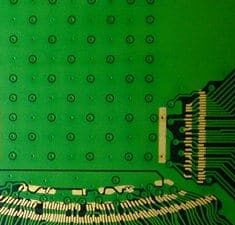

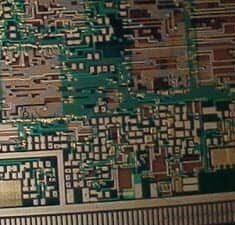

HDI PCB Technology

HDI PCB technology is rapidly becoming a leading segment in the PCB industry. HDI circuits offer significantly higher wiring densities compared to standard PCBs and feature advanced elements such as blind/buried vias, vias-in-pad, and micrometre-level circuit designs.This technology can minimize the size and weight of your boards while improving signal transmission and reducing loss. We offer various construction methods and materials,including flexible HDI PCBs.

- 8 Layer Flip Chip

- High Density Wirebond Array

- Multi Chip Module

more: HDI PCBs

RF PCB Production

Radio Frequency printed circuit boards (RF PCBs) operate at frequencies exceeding 100MHz, with anything above 2GHz classified as Microwave PCBs. Our design team can assist with cost-effective solutions for simple RF circuit boards, and also provide guidance for complex fifty-layer layouts and designs. Our RF PCB capabilities encompass both manufacturing and assembly for prototypes and large production runs. More: RF/Microwave PCB

PCB Education Hub

SFC has launched an innovative platform for engineers and PCB purchasers. The PCB School is a complimentary online resource designed to educate users on various technologies, equipment, and purchasing resources related to printed circuit boards. Discover more: SFC’s PCB School