Alva Industries emphasizes the significance of the motor constant (Km) as a key performance metric for motors utilized in drones and robotics, elaborating on how FiberPrinting™ technology can produce motors with a superior Km compared to other options on the market.

Understanding Motor Constant (Km)

In various contexts, a high Km serves as an essential performance indicator. This metric reflects the torque generated in relation to the heat produced due to inefficiencies within the motor.

The motor constant is defined and calculated as follows:

Km = T/sqrt(Pl), (1)

Here, T denotes torque (in Nm), while Pl represents power loss (in W).

Under certain assumptions discussed later, Km can also be expressed in terms of another parameter—the torque constant kt:

Km = Kt/sqrt(R), (2)

In this equation, Kt is measured in Nm/A, and R signifies resistance (in Ohms).

Kt indicates the potential torque that can be delivered when a specific current is applied.

When using equations (1) and (2), it is indeed crucial to ensure that the parameters and units are accurate. For instance, if Kt is expressed in Nm/Arms, then R in formula (2) must represent the three-phase equivalent resistance, not the line-to-line value RL-L:

R = 3/2*RL-L, (3)

Using Km as a Key Performance Metric

It is crucial to understand that employing Km, particularly as defined by equation (2), assumes that all heat generated is due to copper losses from the current flowing through the motor windings (Pl = I²R).Other sources of loss are not considered. Therefore, Km accurately reflects losses primarily when a motor is delivering torque without movement or at low speeds.

As a result, designs where additional losses are significant may not be suitable for evaluations based solely on Km. Typically,other inefficiencies,such as core losses,magnet-related issues,and windage effects,become more pronounced at higher operational speeds.

Comparative Analysis Using Motor constant

With the aforementioned assumptions in mind, Km remains a valuable tool for comparing motors of similar sizes, voltage ratings, speed capabilities, and power outputs.A motor with a higher Km is expected to deliver greater torque, maintain a lower surface temperature, and consume less energy, thereby demonstrating improved efficiency.

When conducting comparisons, it is essential to ensure that the parameters and units are consistent across all cases. For example,confirming that R represents the three-phase equivalent resistance rather than the line-to-line value is crucial.

Motor Constant in Sizing Decisions

The value of the motor constant becomes particularly critical when selecting motor sizes for applications with limited heat dissipation options, such as medical devices or humanoid robots.

Engineers must assess how much thermal energy can be effectively managed within the system. Typically, thermal resistances are identified to set limits on heat generation. As an example, if a robotic joint can dissipate no more than 100 W before exceeding the design temperature, this information is vital for determining the allowable Km.

For example, if 10 Nm of torque is required and the mechanical structure can only dissipate 100 W, a motor with a minimum Km of 1 Nm/W^1/2 is necessary. This motor must also fit within the available space and operate from the specified power source at the required speed.

Cautions in Using Motor Constant as a Primary Metric

As previously mentioned, Km is less effective in power conversion applications where motors operate at high RPMs compared to low-speed, high-precision scenarios. This is due to the significant non-ohmic losses that occur at elevated speeds.

In slotless motors, speed-dependent losses are lower than in conventional iron-cored slotted designs. For slotless configurations, even at speeds of 3000-5000 RPM, basic conduction losses can account for approximately 90% of total inefficiencies.

Thus, comparing slotless motors against other slotless designs based on Km remains valid for relatively high speeds. However,when contrasting slotless motors with slotted ones for high-speed applications,Km becomes a less reliable metric.

Nonetheless, Km can still be a useful performance indicator when evaluated alongside other application-specific criteria.

Alternative Performance Metrics

Depending on the application, various derivatives of Km may serve as effective performance metrics, such as Km/weight and Km/volume ratios.

As an example, in aerospace applications and exoskeletons, low weight is critical, making the Km/weight ratio a key indicator.However, size is also a consideration, so the Km/volume ratio could be equally important.

The Importance of High Motor Constant in Specific Applications

In medical devices, it is often reasonable to assume an operating room temperature of 25°C. For robotic-assisted surgical systems, large heat sinks for thermal dissipation are typically impractical, making thermal management crucial.

If a patient’s surface temperature limit is set at 45°C, the available temperature rise above ambient (which dictates power dissipation) is only 20°C. Therefore, minimizing heat generation through high-Km motor technology is essential.

Gimbal systems frequently enough rely on battery power, and a higher Km results in reduced energy consumption, leading to longer operational times.

In practice, a higher Km allows for either cooler motor operation at the same torque or increased torque production while maintaining the same surface temperature.

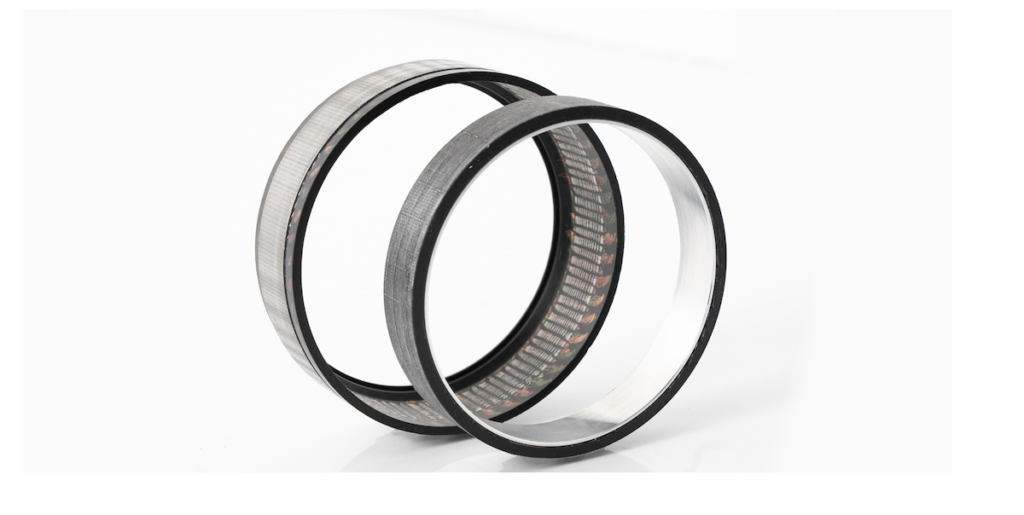

FiberPrinting™: Achieving Superior Motor Constants

Thanks to the unique advantages of FiberPrinting™ technology, such as improved copper fill factor and optimized winding geometry, Alva’s motors generally exhibit a higher Km than comparable alternatives available in the market (Fig. 1).

In Alva’s products, the motor constant remains stable under heavy loads, ensuring reliability even at extremely high peak currents and torques.

Fig. 1.Comparison of various iron-cored (slotted) and slotless motors with an outer diameter of 75 mm and an axial length of 20 mm.

Read the original article >>