Innovative Gimbal Solutions for UAV Applications

HD Air Studio’s advanced multi-sensor gimbals present a wealth of possibilities for commercial drone operations.These gimbals can be outfitted with various payloads, including thermal imaging cameras, LiDAR systems, first-person view (FPV) cameras, lasers, and radar technologies, each designed to gather distinct types of data.

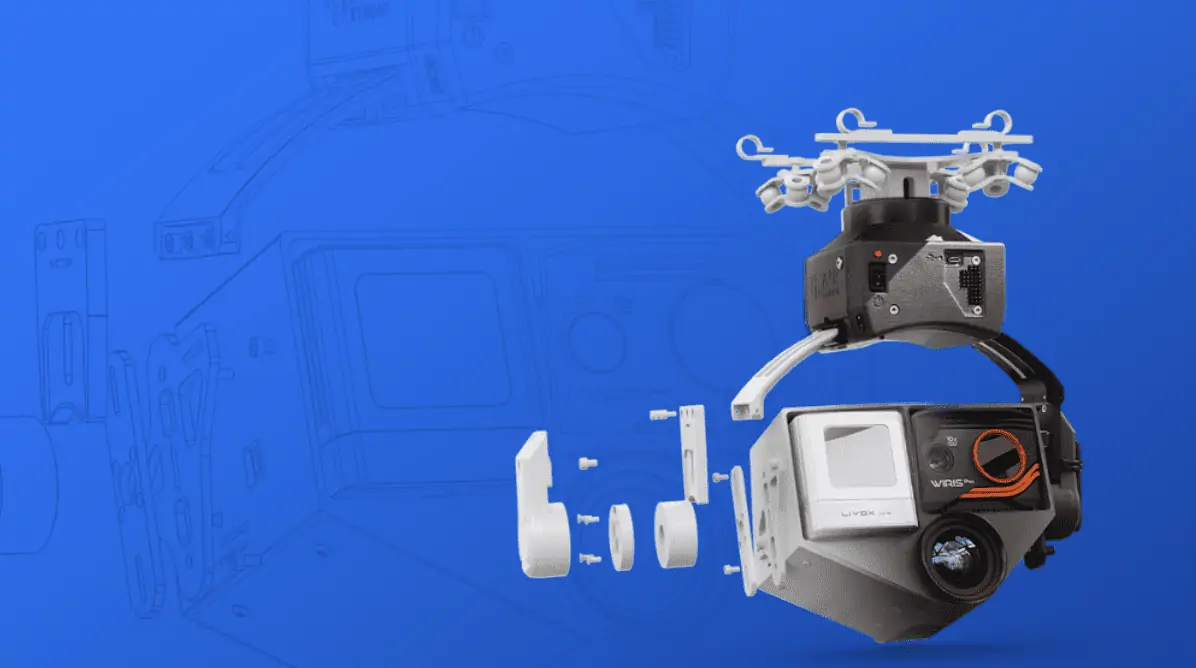

Custom Gimbal Development for Marine Rescue

In a recent initiative, HD Air Studio engineered a specialized gimbal featuring three distinct sensors aimed at enhancing marine search and rescue missions. This custom solution integrates a Wiris Pro thermal camera, a Mako G infrared camera, and a Livox LIDAR system, which can identify objects from distances up to 260 meters.

The Wiris Pro thermal camera boasts a resolution of 640×512 pixels and operates within the 7.5 – 13.5 μm wavelength range, while the Mako G infrared camera provides additional imaging capabilities. This combination allows drones equipped with this gimbal to utilize thermal imaging and neural networks for effective detection and classification tasks. Typically, the gimbal is oriented downward during flight to ensure the thermal camera focuses on the water surface.

Versatile Tracking Capabilities

This gimbal design is also suitable for projects where object tracking is essential. Tracking can be performed manually via remote control or autonomously, with seamless transitions between control modes, making it adaptable for various applications.

Optimizing Weight for Enhanced Flight Performance

HD Air Studio prioritizes maintaining drone flight time by ensuring that the gimbal’s weight does not hinder performance. One of their standard camera gimbals weighs only 600 grams while supporting payloads of up to 800 grams. Achieving an optimal weight-to-carry ratio is crucial, especially when multiple sensors are integrated. The miniaturization of components plays a important role in this optimization. HD Air Studio’s gimbals are robust enough to accommodate two or three sensors without compromising flight duration.

Advanced Manufacturing Techniques

the company employs a combination of aluminum, steel, and plastic CNC machining, along with composite treatments and various 3D printing methods, including multi-jet fusion, to create high-quality gimbal prototypes that rival mass-produced stabilizers.

Weather-Resistant Solutions for Challenging Conditions

Given that drone inspections often occur in adverse weather, HD air Studio designs weatherproof enclosures that integrate seamlessly with their multi-sensor gimbals. For instance, they developed a custom gimbal for an Italian drone service provider, which required a specialized enclosure to withstand harsh environmental conditions. This gimbal, equipped with a Canon 5dS, LiDAR, and FPV camera, is utilized for inspecting offshore wind turbines even in windy and rainy weather, featuring an IP65-rated protective enclosure.