This article by Tyto Robotics explores three distinct techniques for measuring propeller thrust and evaluates their outcomes.

The techniques discussed include the propeller thrust formula, a propeller thrust calculator, and the utilization of a thrust stand for direct measurement.

Understanding propeller thrust is crucial in the aircraft design process.It aids in selecting appropriate components and assessing the maximum useful load.

While calculations based on theoretical models provide a foundation, they have limitations. therefore, we advocate for the use of a thrust stand to empirically measure propeller thrust, ensuring that theoretical calculations are validated.

This article will delve into both the theoretical framework, which relies on equations and assumptions, and the practical approach that involves physical testing to obtain accurate values. Additionally, we will demonstrate how to use a propeller thrust calculator that estimates performance based on user inputs and actual propeller specifications.

Contents Overview:

- Propeller Thrust Formula

- Propeller thrust Estimator

- Measuring Propeller Thrust with a Thrust stand

- case Study: Comparing Thrust from the Estimator and Thrust stand

Figure 1: Flight Stand 150 propeller thrust measurement setup

Propeller Thrust Formula

The thrust generated by a propeller is influenced by its characteristics and the surrounding air. This relationship can be articulated in various forms.

Initially,we will examine the formula for static propeller thrust,applicable when the propeller is stationary in still air.

Next, we will explore the formula for dynamic propeller thrust.

Static Propeller Thrust Formula

Thrust is fundamentally linked to the mass flow rate of air and the variation in air velocity:

The mass flow rate can be defined using air density, the velocity of air at the propeller, and the area swept by the propeller:

Thus, we can reformulate the thrust equation as follows:

While Ve and V0 are measurable, Vp poses a challenge. we can conceptualize thrust as the force exerted on the propeller disk, which corresponds to the pressure differential across the disk multiplied by the area:

Therefore:

To compute propeller thrust, we require the air density, the propeller radius, and the air velocities entering and exiting the propeller.

Dynamic Propeller Thrust Formula

When assessing dynamic propeller thrust, it is essential to factor in the forward speed of the aircraft, along with the RPM and dimensions of the propeller:

This equation, developed by Electric Aircraft Guy, incorporates propeller diameter, pitch, forward airspeed, and RPM.

He has included correction factors to align the results more closely with his measured data, although he estimates a potential underestimation of thrust by 15-30%.

Propeller thrust Estimator

Mejzlik Propellers provides both static and dynamic thrust estimators, which can be utilized to predict the thrust generated by a propeller.

These calculators function by interpolating data derived from the performance of propellers tested by Mejzlik. Their database includes multicopter propellers ranging from 10 inches to 48 inches in diameter.

Static Propeller Thrust Estimator

To calculate static thrust, you simply need to input the following parameters:

- Diameter

- number of blades

- Thrust per propeller

- Air density

- Motor efficiency

We utilized this estimator to determine the payload capacity of a drone. Below is a snapshot of the interface:

Figure 2: Mejzlik’s static thrust estimator interface

Dynamic Propeller Thrust Estimator

The dynamic estimator requires the following inputs:

- Motor specifications (Io, rm, KV, ESC efficiency)

- propeller diameter

- Propeller pitch

- Air density

- Drag

- Aircraft speed

These calculators produce graphs that compare thrust and efficiency across various RPM levels. They also estimate power consumption and allow you to compare your results with similar propeller sizes.

This tool is invaluable if you’re pondering, “What size propeller is suitable for my project?” and need a starting point.

the calculators come with several critically important notes:

- They are specifically designed for multicopter propellers, meaning you cannot modify the propeller pitch (an optimal pitch is pre-selected).

- The RPM and power metrics are relevant only for Mejzlik multicopter propellers.

- Accuracy diminishes as the number of blades increases.

- motor specifications should be confirmed with the manufacturer.

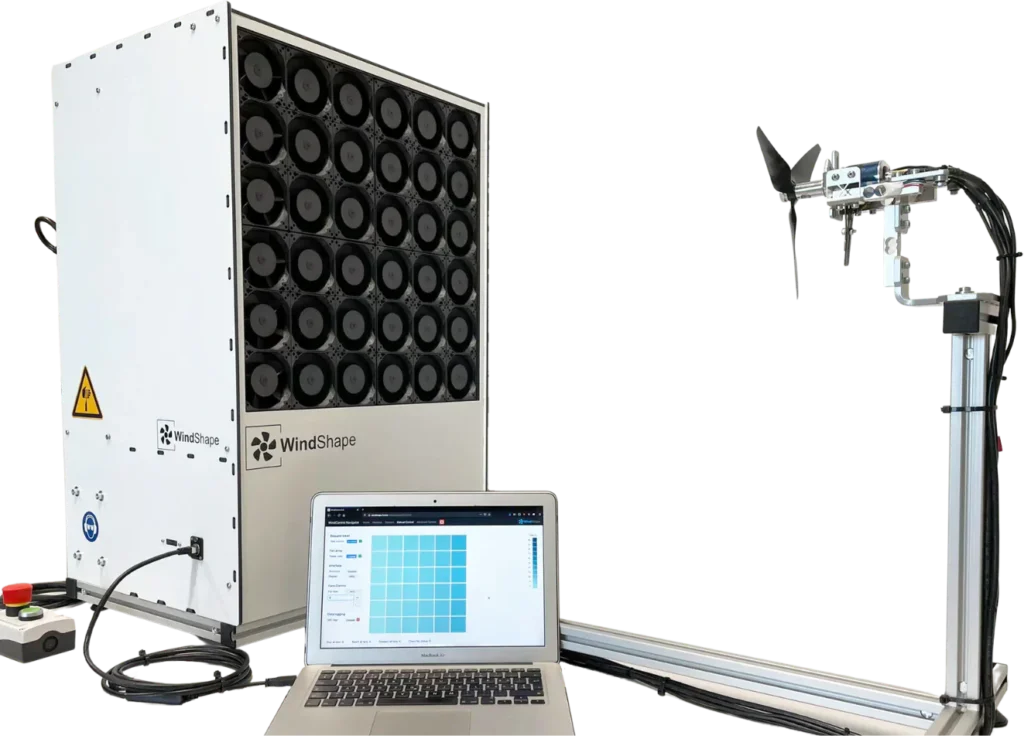

Measuring Propeller Thrust with a Thrust Stand

To accurately determine the thrust produced by a propeller, conducting a test is the most effective approach. Our thrust stands accommodate both static and dynamic testing,ensuring you have the necessary tools for your measurements.

Here’s what you’ll need to conduct a thrust test:

- Propeller

- Motor

- ESC / motor controller

-

Thrust stand

- Power supply

-

Testing software

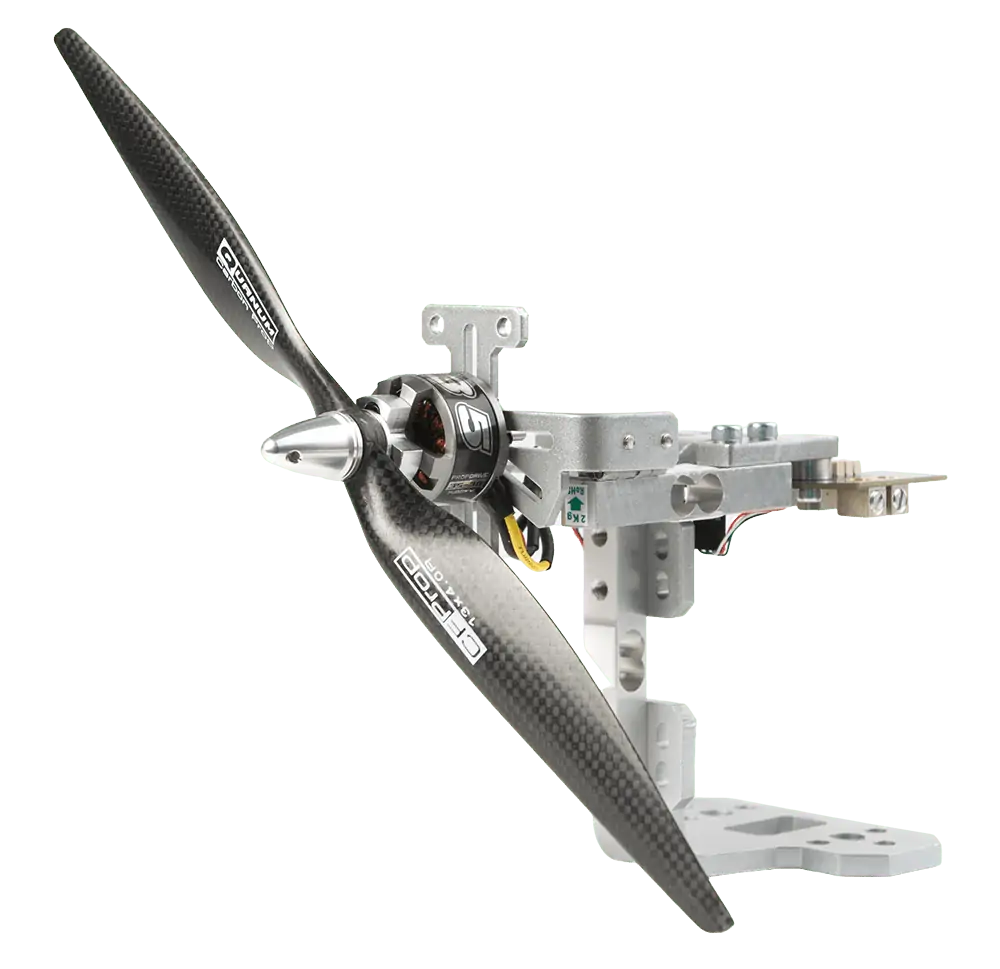

Figure 3: Series 1580 thrust stand propeller configuration

Once you have assembled the necessary equipment, follow these steps to set up your thrust test:

- Secure the thrust stand to a stable surface.

- Connect your ESC and motor to the thrust stand.

- Attach the propeller to the motor.

- Link the thrust stand to the power supply and software.

- Use the software to control the thrust stand and monitor the incoming data.

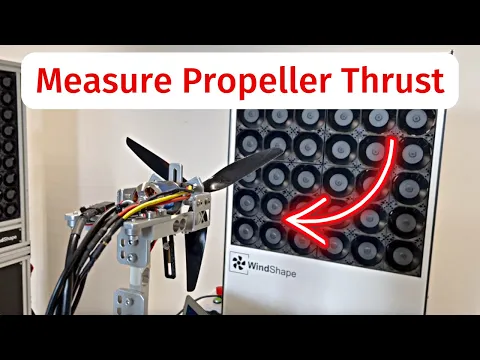

In this video,we demonstrate how to set up the test,including the use of a wind generator for more realistic dynamic results:

For propeller testing, you will likely be interested in both thrust data and propeller efficiency, both of which are recorded by the software.

Here’s an example of the exported data:

Figure 4: Propeller thrust and efficiency data from software

case Study: Comparing Thrust from the Estimator and Thrust Stand

Let’s consider a scenario to compare the results from these two methods.

Assume we have a 48-inch, two-blade propeller, and the average air density is 1.225 kg/m³.

Recent findings indicate that the average maximum efficiency of a brushless motor is approximately 78%, which we will use for our calculations.

For this example, we will utilize the static thrust estimator and a stationary thrust stand without a wind tunnel.

Propeller Thrust Estimator Results

by inputting these values into the static propeller thrust estimator, we can predict the thrust:

Figure 5: Output from the propeller thrust estimator

The estimator indicates that at an RPM of 1880, the thrust is 20 kgf.

It also provides a brief table with estimated RPM and thrust values, along with a graph illustrating their relationship (see figure 7).

Thrust Stand results

We employed our Flight Stand 50 for this test, capable of measuring up to 50 kgf of thrust and 30 Nm of torque.

Figure 6: Flight Stand 50 thrust stand with 48-inch propeller

We conducted a ramp test from 0 to 2000 RPM with the 48-inch propeller.

After exporting the test data, we selected points based on the RPM values provided in the thrust estimator’s table. we plotted these points side by side and added trend lines, as shown in figure 7 below.

Interestingly, the thrust estimator underestimated the propeller’s performance. At all RPM levels, the thrust measured by the thrust stand exceeded the estimates from the calculator.

This outcome is generally preferable,as it is better for the calculator to underestimate performance than for the aircraft to underperform.

Figure 7: Thrust data comparison between the estimator and thrust stand

This discrepancy may stem from minor variations in the propeller; the one we tested might have a different pitch than what the calculator assumes.

This illustrates that for accurate thrust and performance assessments of your propeller, physical testing is essential.

Final Thoughts

there are numerous methods to estimate the thrust generated by your propeller using formulas and thrust estimators.

Though, to ascertain the actual thrust produced in your propulsion system, the most reliable approach is to conduct tests using a thrust stand.

If you are interested in testing your propellers, consider our range of propeller test stands:

-

Series 1580

– measures up to 5 kgf of thrust

-

Flight Stand 15/50

– measures up to 50 kgf of thrust

-

Flight Stand 150

– measures up to 150 kgf of thrust